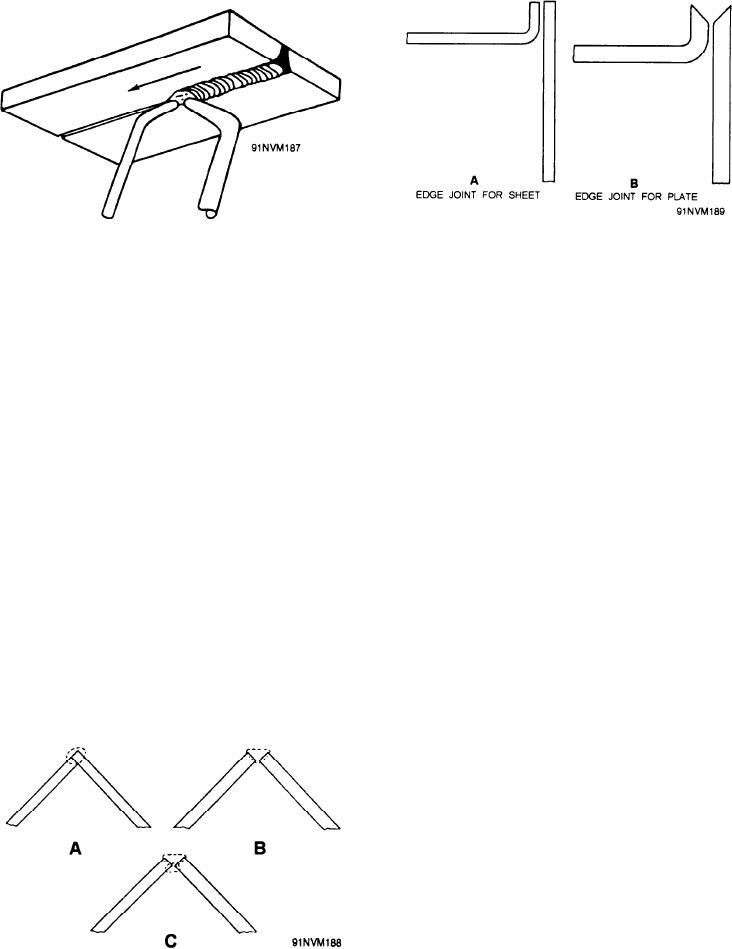

Figure 8-35.--Edge joints for sheet and plate.

Figure 8-33.--Welding a butt joint in the overhead position.

heavier sections, V-bevel or U-groove the lapped plate

reinforcement of the weld. Keep the flame in such a

to permit penetration to the root of the joint.

position that it will support the molten metal and

View B of figure 8-34 shows an OPEN corner joint

distribute it along the joint. Use a small filler rod; this

that is often used on heavy sheets and plates. To make

will help you to keep the puddle small. In many

this joint, melt down the edges of the plate and add

overhead welding jobs, it is possible to weld from one

enough filler metal to build up the comer from one

side only. In such cases, particular care is required to

side.

make sure the heat is evenly distributed, so that one

plate will not be burned through.

View C shows an open corner joint that is welded

from both sides. First weld the joint from the outside,

Making a Corner Joint

then reinforce the joint and seal it (as for use in drip

pans) from the inside with a seal bead weld.

The comer joint is used to join the edges of two

plates when the surfaces of the plates make a 90-degree

angle with each other. Figure 8-34 shows three designs

Making an Edge Joint

that are commonly used for corner joints. The

CLOSED comer joint (view A) is used on lighter

Edge joints are used mainly to join the edges of

sheets and plates where strength requirements for the

sheet metal and to weld reinforcing plates on flanges

joint are not a factor. In making this joint, melt the

of I-beams or edges of angles. Figure 8-35 shows two

overlapping edge with the torch and add only a small

common types of edge joints. The joint shown in view

amount of filler metal. When using this joint design for

A is used for welding thin sheets; this joint requires no

edge preparation other than cleaning the edges and

tacking them together. The joint shown in view B is

used for heavier plate. To make this joint, bevel the

edges to allow good penetration and fusion of the side

walls. In making both of these joints, use enough filler

metal to fuse both edges and to reinforce the joint.

Making a Lap Joint

The lap joint is the simplest of all weld joints and

is formed by overlapping two plates of metal. Lap

joints may be welded from one side or from two sides.

They are stronger when welded from both sides, but

Figure 8-34.--Corner joints. A. Closed joint. B. Open joint,

even a lap joint that is welded from only one side is

welded from one side. C. Open joint, welded from both

stronger than a butt joint in some applications.

sides.

8-25