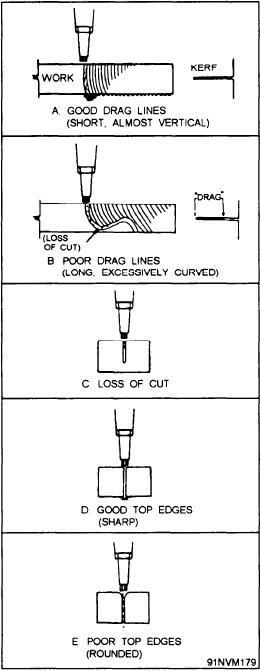

are short and almost vertical, the smoothness of the

the top edges, and (4) the amount of slag adhering to

sides, the sharpness of the top edges, and the slag

the metal.

conditions are almost sure to be satisfactory.

DRAG LINES.--Drag lines are the line markings

SMOOTHNESS OF SIDES.--A satisfactory

that show on the cut surfaces. Good drag lines are

oxyacetylene cut shows smooth sides. A grooved,

almost straight up and down, as shown in view A of

fluted, or ragged cut surface indicates a cut of poor

figure 8-25. Poor drag lines are long and irregular or

quality.

excessively curved, as shown in view B of figure 8-25;

drag lines of this type indicate poor cutting procedure

SHARPNESS OF TOP EDGES.--The top edges

which may also result in loss of the cut (views B and

resulting from an oxyacetylene cut should be sharp and

C of fig. 8-25).

square (view D, fig. 8-25). Rounded top edges, such

as those shown in view E of figure 8-25, are not

Drag lines are probably the best single indication

considered satisfactory. Melting down of the top edges

of the quality of an oxyacetylene cut. If the drag lines

may result from incorrect preheating procedures or

from moving the torch too slowly.

SLAG CONDITIONS.--An oxyacetylene cut is

not considered satisfactory if slag adheres so tightly to

the metal that it is difficult to remove.

SAFETY PRECAUTIONS

In all cutting operations, be careful to see that hot

slag does not come in contact with any combustible

material. Globules of hot slag can roll along a deck for

quite a distance. Do not cut within 30 or 40 feet of

unprotected combustible materials. If combustible

materials cannot be removed, cover them with sheet

metal or noncombustible materials. Keep the acetylene

and oxygen cylinders far enough away from the work

so that hot slag will not fall on the cylinders.

Many of the safety precautions discussed in

chapter 1 of this training manual apply to cutting as

well as to welding. Be sure that you are entirely

familiar with all appropriate safety precautions before

attempting any oxyacetylene cutting operation.

OXYACETYLENE WELDING

TECHNIQUES

Oxyacetylene welding may be accomplished by

either the forehand or the backhand method. Each of

these techniques has special advantages; you should

be skillful with both. Whether a technique is

considered to be forehand or backhand depends on the

relative position of the torch tip and filler rod in

relationship to the direction of welding. The best

technique to use depends upon the type of joint, its

position, and the necessity for controlling the heat on

the parts to be welded.

FOREHAND WELDING (also called puddle weld-

Figure 8-25.--Effects of correct and incorrect cutting

ing or ripple welding) is the oldest method of welding.

procedures.

8-21