round spot has been heated to a bright red. Introduce

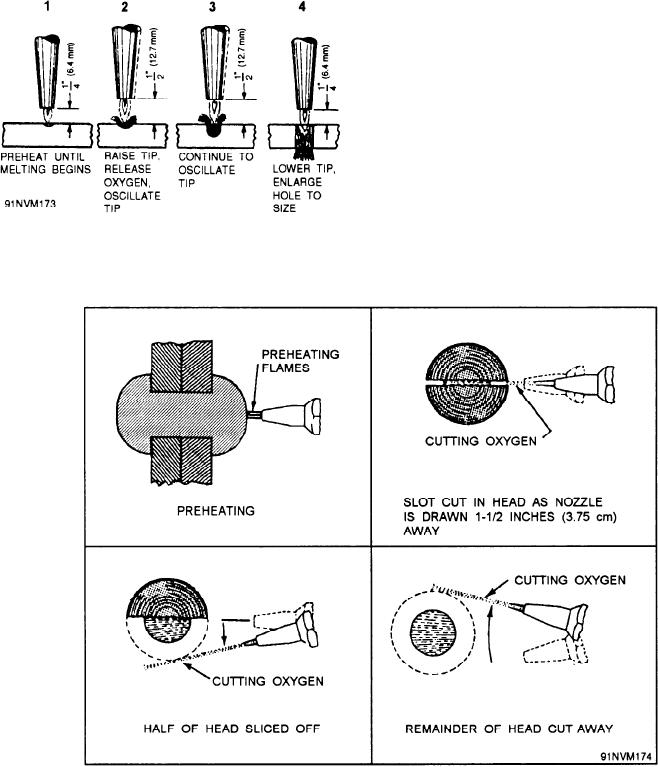

Piercing Holes

the cutting oxygen by gradually depressing the oxygen

The cutting torch is also a valuable tool for

lever, and at the same time slightly raise the tip away

piercing holes in steel plate. The steps are illustrated

from the work to keep from blowing slag back onto the

in figure 8-19. Lay the plate out on two firebricks so

cutting tip. As you start raising the torch and

that the flame will not hit something else when it bums

introducing the cutting oxygen, start rotating the torch

through the plate. Hold the torch over the hole location

with a spiral motion. This will cause the molten slag

with the tips of the inner cone of the preheating flames

to be blown out of the hole. The hot slag may fly

about one-fourth inch above the surface of the plate.

around, so BE SURE your goggles are well fitted to

Continue to hold the torch in this position until a small

your eyes and face, and avoid having your head

directly above the cut.

If you need a larger hole, outline the edge of the

hole with a piece of chalk, and follow the procedure

given in the previous paragraph. Start the cut from the

hole that you have pierced by moving the preheating

flames to the normal distance and by working to and

following the line that has been drawn on the plate.

Round holes can be made by using a cutting torch with

a radius bar attachment.

Cutting Rivets

When you are required to remove rivets from

plates that are to be disassembled, you will find the

cutting torch a good tool. The cutting procedure is

Figure 8-19.--Piercing a hole with an oxyacetylene cutting

shown in figure 8-20. Use the preheating flames of the

torch.

Figure 8-20.--Using a cutting torch to remove the head of a rivet.

8-17