Occasionally the cleaning of the tips will cause

enlargement and distortion of the orifices even if the

proper tip cleaners are used. If the orifices become

enlarged, you will get shorter and thicker preheating

flames; in addition, the jet of cutting oxygen will

spread rather than leave the torch in the form of a long

thin stream. If the orifices become belled for a very

short distance at the end, it is sometimes possible to

correct this condition by rubbing the tip back and forth

against emery cloth on a flat surface. This wears down

the end of the tip where the orifices have been beveled,

thus bringing the orifices back to their original size.

Obviously, this procedure would not work if the

enlargement is very great or if the belling extends more

than a slight distance into the orifice.

After reconditioning a tip, you may test it by

lighting the torch and observing the preheating flames.

If the flames are too short, the orifices are still partially

blocked. If the flames snap out when the valves are

closed, the orifices are still distorted.

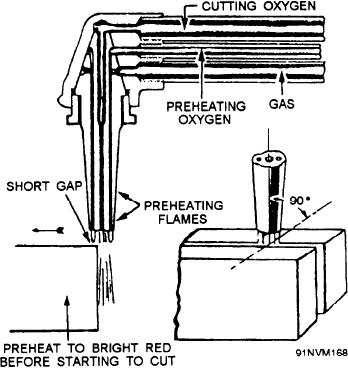

Figure 8-14.--Position of torch tip for starting a cut.

If the tip seat is dirty or scaled so that it does not

fit properly into the torch head, you should heat the tip

to a dull red and quench it in water. This will loosen

If the cut is being started correctly, a shower of

sparks will fall from the opposite side of the work,

the sale and dirt enough so that they can be rubbed off

indicating that the cut is going all the way through.

with a cloth.

Move the cutting torch forward along the line just fast

enough for the cut to continue to penetrate the work

OXYACETYLENE CUTTING

completely. If you have made the cut properly, you

OPERATIONS

will get a clean, narrow cut that looks somewhat like

one made by sawing. When cutting round bars or

Before beginning any oxyacetylene cutting opera-

heavy sections, you can save time and gas if you raise

tion, be sure you have selected the right size tip for the

a small burr with a chisel where the cut is to start. This

job. Follow the manufacturer's recommendations con-

small raised portion will heat quickly, and cutting can

cerning tip sizes to use for different kinds of work. The

be started sooner. If you have a cut to start from the

oxygen and acetylene pressures to be used with various

center on some portion of metal other than the edge,

sizes of tips are also given by the manufacturer. Before

use the following method for starting the cut. Preheat

fitting a cutting tip into the torch head, inspect the tip

to a bright red the spot on the surface where the cut is

carefully to be sure that it is clean and not distorted,

to start. Tilt the torch at an angle of about 45 from the

and that the orifices are not clogged with slag.

perpendicular, in line with the direction of the cut.

Press the cutting oxygen lever very slowly. As the

Cutting Low-Carbon Steel

torch begins to cut, start righting it to a perpendicular

position to the surface of the plate. Continue to right

To cut low-carbon steel with the oxyacetylene

the position of the torch gradually as it cuts until it is

cutting torch, adjust the preheating flames to neutral.

at 90 to the surface of the plate and is cutting all the

Hold the torch perpendicular to the work, with the

way through. Move it forward along the line of cut as

inner cones of the preheating flames about

fast as complete penetration can be accomplished. If

one-sixteenth inch above the end of the line to be cut,

you do not follow this procedure, you are likely to blow

as shown in figure 8-14. Hold the torch in this position

the slag back on the cutting tip, clogging the orifices

until the spot you are heating is a bright red. Introduce

or otherwise damaging the equipment. When you have

the cutting oxygen by depressing the oxygen lever

started a cut, move the torch slowly along the cutting

mark or guide. As you move the torch along, watch the

slowly but steadily.

8-14