However, a MAPP gas leak is easy to detect and can be

225-cubic foot acetylene cylinder, is 120 pounds (54.0

repaired before it becomes dangerous.

kg) when full.

MAPP toxicity is rated "very slight," but high

MAPP cylinders contain only liquid fuel. There is

concentrations (5,000 ppm) may have an anesthetic

no cylinder packing of acetone to impair fuel with-

effect. Local eye or skin contact with MAPP gas vapor

drawal. For heavy-use situations, a MAPP cylinder

causes no adverse effect. However, the liquid fuel will

will deliver more than twice as much gas as an acety-

cause dangerous frostlike burns due to the temperature

lene cylinder and for longer periods of time. The entire

at which MAPP gas must be stored.

contents of a MAPP cylinder can be used, as there is

no acetone that could be drawn into the regulators or

OXYGEN

torch. As the gas bums with oxygen, it produces a

flame temperature of 5300F (2950C) and will equal

Oxygen is a colorless, tasteless, odorless gas that is

or exceed the performance of acetylene for cutting,

slightly heavier than air. Oxygen will not bum by itself,

heating, and brazing due to its superior heat transfer

but it will support combustion when combined with

characteristics.

other gases. Extreme care must be taken to ensure that

compressed oxygen does not become contaminated with

MAPP is nonsensitive to shock and nonflammable

hydrogen or hydrocarbon gases or liquids, unless the

in the absence of oxygen. There is no chance of an

oxygen is controlled by such means as the mixing cham-

explosion if a cylinder is bumped, jarred, or dropped.

ber of a torch. A highly explosive mixture will be formed

The cylinders may be stored or transported in any

if uncontrolled compressed oxygen becomes contami-

position with no danger of an explosive air pocket

nated. Oxygen should NEVER come in contact with oil

being formed.

or grease.

The characteristic odor, while harmless, gives

Oxygen cylinders are supplied in several sizes.

warnings of fuel leaks in the equipment long before a

The size most commonly used aboard ship is 9 1/8

dangerous condition can occur.

inches in diameter, weighs about 145 pounds, and has

a capacity of 200 cubic feet. At 70F, the gas is under

MAPP gas is not restricted to a maximum working

a pressure of 1800 psi.

pressure of 15 psig, as is acetylene. In jobs requiring

higher pressures and gas flows, MAPP at the full

REGULATORS

cylinder pressure of 95 psig at 70F (21 C) can be used

safely.

The gas pressure in a cylinder must be reduced to a

suitable working pressure before it can be used. This is

MAPP Gas Safety

done by a regulator or reducing valve. Regulators are

either the single-stage or the double-stage type. Single-

Liquified MAPP gas is insensitive to shock. A

stage regulators reduce the pressure of the gas in one

MAPP gas cylinder will not detonate when dented,

step; two-stage regulators do the same job in two steps

dropped, hammered, or even incinerated. It may also

or stages. Less adjustment is generally necessary when

be safely used up to full cylinder pressures. The gas

two-stage regulators are used.

vapors, up to 419F and 285 psig, will not decompose

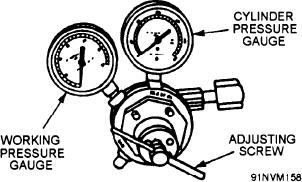

Figure 8-4 shows a typical single-stage regulator.

when subjected to an energy source in the absence of

The regulator mechanism consists of a nozzle through

oxygen. The vapor also is stable up to 600F and 1,100

psig when exposed to an 825F probe. The explosive

limits of MAPP gas are 3.4 percent to 10.8 percent in

air, or 2.5 percent to 80 percent in oxygen. As you can

see, these limits are very narrow in comparison with

that of acetylene.

MAPP gas has a highly detectable odor. The smell

is detectable at 100 ppm, or at a concentration 1/340th

of its lower explosive limit.

Small fuel-gas systems may leak 1 or 1 1/2 pounds

of fuel or more in an 8-hour shift. Fuel-gas leaks are

often difficult to find, and many times go unnoticed.

Figure 8-4.--Single-stage regulator.

8-3