Assemble the swage head assembly according to the

Pipe Inspection and Insertion Marking

manufacturer's directions and swage the fitting. After

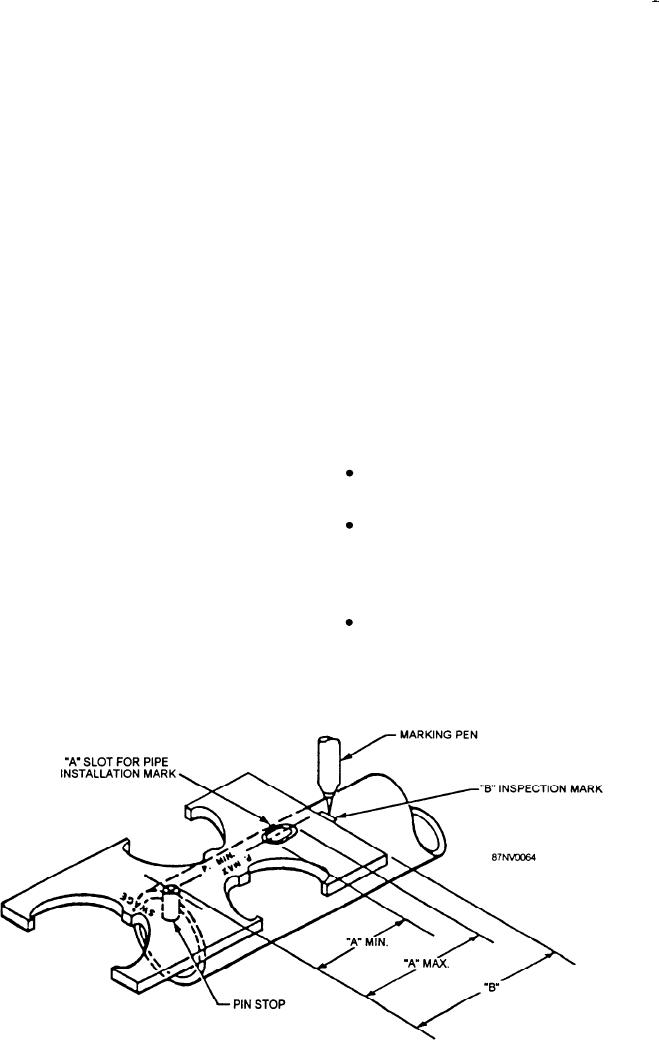

Using the proper marking/inspection gauge, verify

swaging, inspect the swage fitting dimensions

the OD of the pipe and fitting as shown in figure 16-25.

according to the latest manufacturer's technical manual.

The P-MAX gauge must fit over the pipe/fitting in the

region of the pipe/fitting contact; the P-MIN must not

ELASTIC STRAIN PRELOAD (ESP)

make three-point gauge contact or have two points 90

degrees apart. Check two places on the pipe 90 degrees

FITTINGS

apart for ovality. Refer to figure 16-26 for gauge usage.

After checking and verifying the pipe diameter and

ESP fittings provide the same advantage as the

roundness, use the marking/inspection gauge to lay out

SMF. There are many similarities in installation

the inspection and insertion marks. Refer to the

procedures of the two fittings. However, the basic

manufacturer's technical manual for proper insertion

design of the ESP fittings is different from that of the

depth. If the pipe wall thickness is greater than 0.125

SMF. The hydraulic pressure is applied in a horizontal

inch, use a scriber to mark the pipe. For pipe wall

position, as opposed to vertical. Their installation is

thickness of less than 0.125 or stainless steel material

use a chloride-free marking pen.

limited to copper pipe, class 200 90/10 copper nickel

pipe up to 2 l/2 inches nominal and 3 16 stainless steel

System Fit-up

l/4 inch schedule 80 pipe used in Halon systems. The

following equipment is necessary to install ESP fittings:

After marking the pipe, you are ready to install the

Locking power head--Consists of a stationary

SMF. Apply a lubricant compatible with the system

fluid to the pipe end and insert the pipe end into the

and a movable jaw assembly.

fitting. Keep rotation and twisting to a minimum when

Marking/inspection gauge--Used to verify the

inserting the pipe. A slight resistance should be

OD of pipe or tube, to locate installation and

encountered during insertion of the pipe into the fitting.

inspection marks, and to verify seal retention of

If no resistance is encountered, recheck the pipe to the

fitting match-up and the fitting for placement and

after-swage dimensions.

damage of the elastomeric seal. Position the end of the

Portable hydraulic power supply--Converts

fitting over the pipe installation mark so that some

mechanical, electrical, or pneumatic energy to

portion of the mark is visible. You must position the pipe

hydraulic energy.

in the fitting to ensure an acceptable joint (fig. 16-27).

Figure 16-25.--Using marking/inspection gauge to mark pipe.

16-24