7. As you bend the segments, you will probably

reducing tube ends, sizing tube ends, and joining tube

have to move the template out of the way. Be sure to

ends.

keep it on the centerline of the piping when you move

it.

BENDING TUBING AND PIPE

8. Continue bending the segments and check the

Tubing and pipe can be bent by the methods

tubing with the template until the tubing has been bent

described earlier in this chapter. Your main problem will

to the angle of the template.

be to prevent wrinkles and flat spots. Wrinkles are

You can also use the segment method of bending to

caused by compression of the pipe wall at the throat

make hot bends in sand-filled pipe. Suppose, for

(inside) of the bend. Flat spots are caused by lack of

example, that you need to bend a piece of copper tubing

support for the pipe wall, by stretch in the heel (outside)

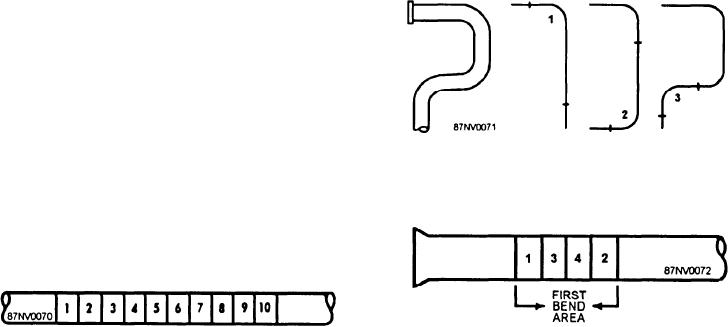

to a 180-degree bend and then to a 90-degree bend, as

of the bend, or by improper heating.

shown in figure 16-32. Treat the total bending operation

If the pipe is properly packed and properly heated,

as though it consisted of three separate 90-degree bends,

you can prevent wrinkles and flat spots. You can do this

and follow this procedure:

by bending the pipe in segments so that the stretch is

1. Properly pack the tube with sand and use the

spread evenly over the whole bend area. When a pipe is

wire template to lay out the bend area of the first bend.

bent, the stretch tends to occur at the middle of the bend.

Do NOT mark the area of the second bend until the first

If the bend area is divided into a number of segments

bend has been made; some stretch will occur when the

and then bent in segments, the stretch will occur at the

first bend is made. Also, the third bend area cannot be

center of each segment. Therefore, the stretch will be

laid out until after the first and second bends have been

spread fairly evenly over the whole bend area. Another

made.

advantage of bending in segments is that this is about

2. Divide the first bend area into four segments and

the only way you can follow a wire template accurately.

mark them as shown in figure 16-33. Use chalk or

Use the following procedure to make a segmented

soapstone to mark the numbers.

90-degree cold bend in copper-nickel tubing:

3. Place a baffle behind the first segment and heat

1. Lay out the bend area from the wire template.

the segment to a full red.

2. Divide the bend area into a number of segments,

4. Apply pressure and bend the first segment about

as shown in figure 16-31. Remember, the more seg-

one-fourth of the required amount (about 22 1/2).

ments you use, the smoother the bend will be. The

number of segments that will work best in any particular

case will depend on the size (diameter) and wall

thickness of the tubing, the degree of the bend, and other

factors that you will learn on the job.

3. Bend each segment slightly. Bend the last two

or three segments less than the others to allow for

adjustments.

4. Check the bend with the wire template.

Figure 16-32.--Tubing bent to 180 and then to 90.

5. Starting at the first segment again, bend each

segment to a slightly greater angle than you did the first

time.

6. Check the tubing again with the wire template.

Figure 16-33.--Layout for first 90-degree bend.

Figure 16-31.--Layout for bending tubing in segments.

16-29