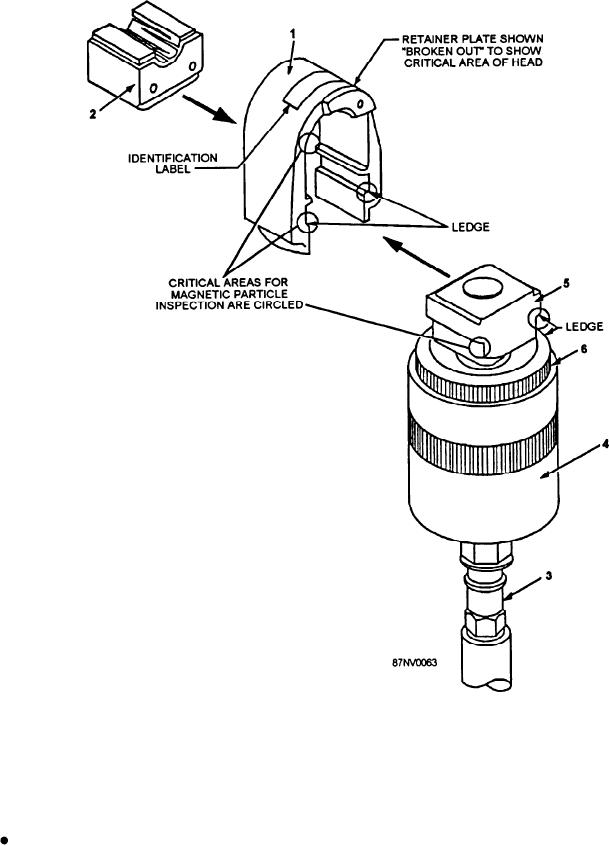

5 . Strut

3. Pressure line to hydraulic power supply

1. Yoke assembly

6. Knurled nut

4. Power unit

2. Die holder assembly (with lower die half shown)

Figure 16-24.--Swage tool component parts.

straight section of pipe with no wrinkles, bulges, or

Portable hydraulic power supply--Converts

dents. If the pipe is galvanized, you should remove the

mechanical, electrical, or pneumatic energy to

galvanization with emery cloth until a smooth round

hydraulic energy.

surface is obtained. The pipe end should be cut no more

than 3 degrees off square, but a cut of 5 degrees off

Pipe Preparation

square is acceptable. Apply a chamfer of l/16 inch at

approximately 30 degrees of the cut end and deburr the

Pipe end preparation is improtant to ensure a good

inside of the pipe, using 120 or 150 grit aluminum-oxide

contact area between the pipe and and the elastomeric

cloth to remove surface defects.

seal within the fitting. The SMF must be installed in a

16-23