APPENDIX IV

DERIVATION OF FORMULAS FOR

DIAMETRAL PITCH SYSTEM

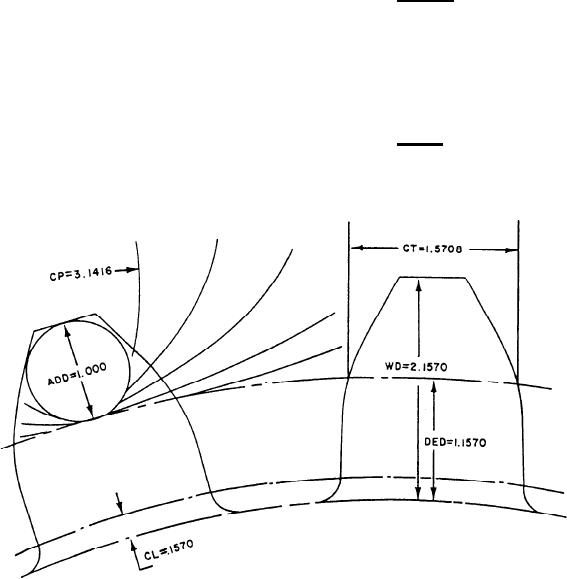

1. TOOTH ELEMENTS based on a No. 1

c. Circular Thickness (CT)1.5708

diametral pitch gear (fig. AIV-1)

(1) One-half of the circular pitch, measured

at the pitch line.

a. Addendum (ADD).000

d. Clearance (CL)0.15708

(1) The distance from the top of the tooth to

the pitch line.

(1) One-tenth of the chordal thickness;

move decimal one place to the left.

b. Circular Pitch (CP)31416

e. Dedendum (DED)1.15708

(1) The length of an arc equal to the

(1) The sum of an addendum plus a clearance.

circumference of a 1inch circle, covers one tooth and

one space on the pitch circle.

(2) 1.000 - ADD

(2) Measure the circular pitch on the pitch

0.1570 - CL

line. If you could draw a circle inside the tooth using

1.1570 - DED

the 1-inch addendum as the diameter, the circumference

of the circle would be 3.1416. Using your imagination,

f. Working Depth (WKD)2.000

break the circle at one point on the circumference,

(1) The sum of two addendums.

imagining the circumference is a string. Lay the

(2) 1.000 - ADD

imaginary string on the pitch line at one side of the

tooth. Stretch the other end as far as possible on the pitch

+1.000 - ADD

line; it will stretch to a corresponding point on the next

2.000 - WKD

adjacent tooth on the pitch line.

Figure AIV-1.Tooth elements on a No. 1 diametral pitch gear.

AIV-1