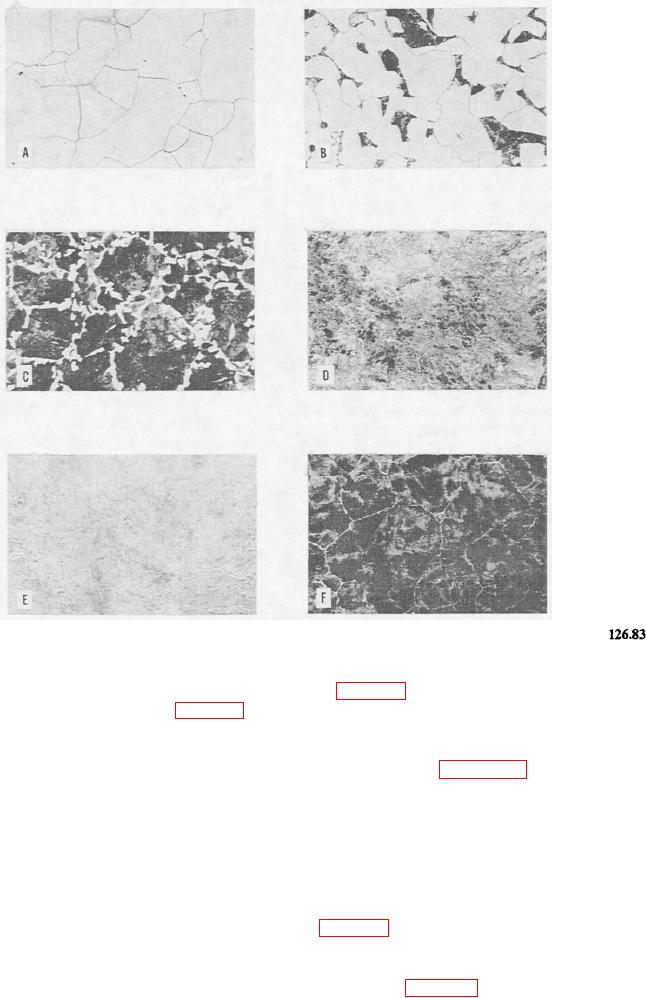

Figure 15-14.--Microstructural constituents of slowly cooled carbon steel (all etched with either picral or nital).

absorb a considerable amount as pure austenite, the

(ECF in fig. 15-11) will decompose partly or completely

maximum being about 2 percent at 2,065F (fig. 15-11,

into austenite and graphite.

point E). The solid solution of carbon in delta iron is

The part of the iron-carbon phase diagram that is

called delta ferrite, and the solid solution of carbon in

concerned with the heat treatment of steel is reproduced

alpha iron is called alpha ferrite, or, more simply, ferrite.

on an expanded scale in figure 15-13. Regardless of the

The physical process by which iron-carbon alloys,

carbon content, steel exists as austenite above line

especially those containing less than about 0.6 percent

GOSE. Steel of 0.83 percent carbon is designated as

of carbon, solidify is rather complicated. All you really

eutectoid steel, and those with lower or higher carbon

need to know, however, is that all iron-carbon alloys

as hypoeutectoid and hypereutectoid, respectively.

containing less than 2 percent of carbon (steel) will,

An eutectoid steel, when cooled at very slow rates

immediately or soon after solidification is complete,

from temperatures within the austenitic field, undergoes

consist of single-phase austenite. Cast irons containing

no change until the temperature reaches 1,330F (line

greater than 2 percent carbon will consist of two phases

PSK) (fig. 15-13). At this temperature (known as the A1

immediately after solidification-austenite and

temperature), the austenite transforms completely to a

cementite. Under some conditions this cementite

mixture of ferrite and cementite having a typical

formed on cooling through the temperature 2,065F

lamellar structure (fig. 15-14, view E). The mixture is

15-15