Figure 15-17.--Influence of carbon on the start of martensite

of critical importance. Somewhat slower rates of

cooling above and below this temperature range can be

tolerated and a completely hardened steel (one that is

completely martensite) can be obtained if the cooling

through the temperature interval at the nose of the

S-curve is sufficiently fast. In practice, however, steels

are usually cooled rapidly from the quenching

temperature to relatively low temperatures (20 to

250F) and then tempered immediately to prevent

Although the discussions of the decomposition of

austenite have been limited to a steel of eutectoid

composition, other steels behave in a similar manner, at

different temperatures and times of reaction. In

hypoeutectoid steels, free ferrite plus pearlite are

formed if transformation begins above the temperature

range at the nose of the S-curve. The amount of fre-

ferrite decreases as the temperature of transformating

approaches the nose of the curve. In hypereutec,

steels, free ferrite plus pearlite are formed if

transformation occurs above the nose. `The time for the

start of the transformation at the nose increases as the

carbon increases up to the eutectoid composition, and

then decreases with further increase in carbon. That is,

the nose is shifted to the right on the time axis (fig.

15-15) as the carbon is increased to 0.8 percent and back

to the left with further increases in carbon content.

The temperature of formation of bainite is not

appreciably affected by carbon content, but the time for

its formation increases with the carbon.

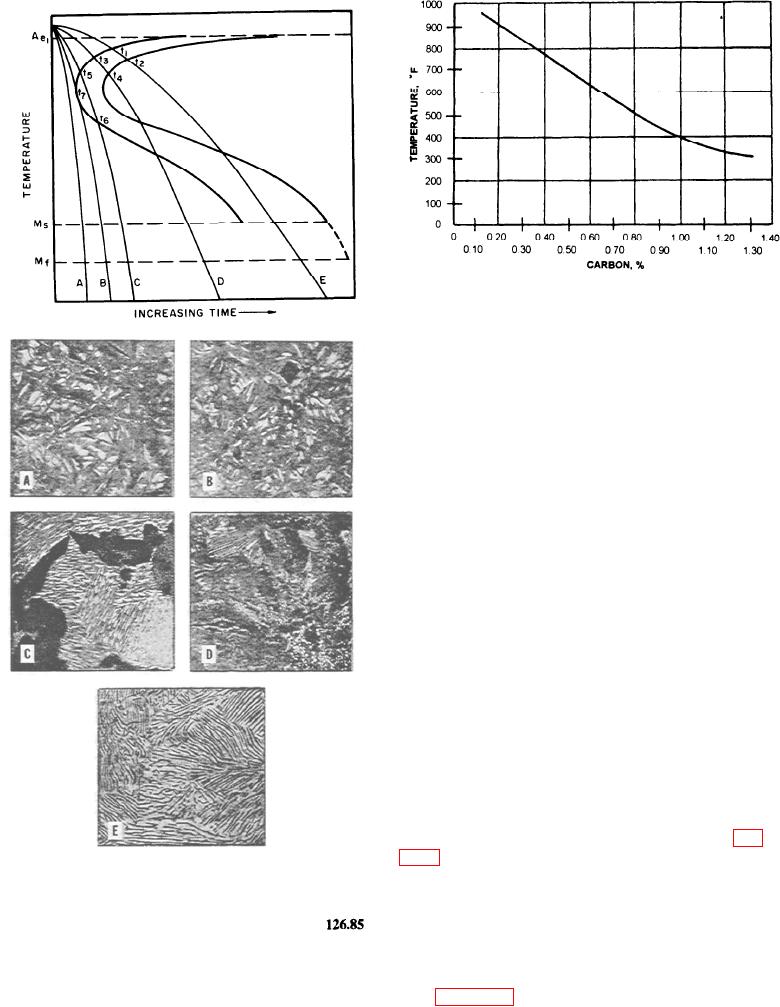

Figure 15-16.--Schematic diagram illustrating the relation

Both the Ms and the Mf temperatures are lowered

between the S-curve, continuous cooling curves, and

resulting microstructures of eutectoid carbon steels.

significantly by increasing carbon content, as shown for

M, in figure 15-17. The Mf temperatures of the plain-

carbon steels have not been adequately determined.

15-19