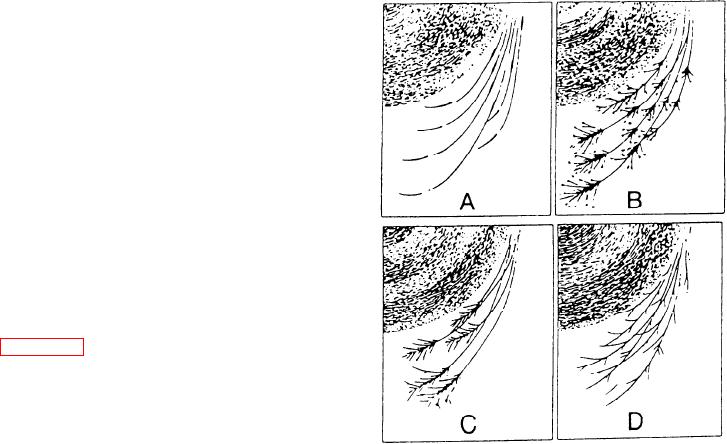

indicate a high carbon content. View C shows shafts,

with that of known specimens. Many shops maintain

forks, and sprigs that indicate a medium carbon

specimens of known composition for this purpose.

content. View D shows shafts and forks that indicate

Proper lighting conditions are essential for good

a low carbon content.

spark testing. You should perform the test in an area

where there is enough light, but no harsh or glaring

The greater the amount of carbon in a steel, the

light. You may find that many ships have a spark test

greater the intensity of bursting in the spark stream.

cabinet. Generally, these cabinets consist of a box

To understand the cause of the bursts, remember that

with a dark, painted interior, mounted on top of a

while the spark is glowing, the carbon in the particle

workbench. A bench grinder is mounted inside the

contacts oxygen in the air and is burned to carbon

cabinet. Test specimens of known composition are

dioxide (CO2). The CO2 in the gaseous state

stored in shelves at the end of the cabinet. Where

increases in volume and builds up pressure that is

relieved by explosions of the particles. If you

possible, the testing area should be away from heavy

drafts of air. Drafts can change the tail of the spark

examine the small steel particles under a microscope

stream and may result in improper identification.

when they are cold, you'll see they are hollow spheres

Generally speaking, a suitable grinding wheel for

with one end completely blown away.

spark testing is an 8-inch wheel of 30 to 60 grains

Steels with the same carbon content but different

turning at 3,600 rpm. This provides a surface speed

alloying elements are not always easily identified

of 7,537 feet per minute.

because alloying elements affect the carrier lines, the

bursts, or the forms of characteristic bursts in the

The speed of the grinding wheel and the pressure

spark picture. The effect of the alloying element may

you exert on the samples greatly affect the spark test.

retard or accelerate the carbon spark or make the

The faster the speed of the wheel, the larger and

carrier line lighter or darker in color. Molybdenum,

longer the spark stream. The pressure of the piece

for example, appears as a detached, orange-colored,

against the wheel has a similar effect: the more

spearhead on the end of the carrier line. Nickel seems

pressure you apply to the test piece, the larger and

to suppress the effect of the carbon burst. But, the

longer the spark stream. Hold the test piece lightly

but firmly against the wheel with just enough pressure

to prevent the piece from bouncing. Remember, you

must apply the same amount of pressure to the test

specimen as to the sample you are testing.

Be sure to keep the wheel clean at all times. A

wheel loaded with particles of metal will give off a

spark stream of the type of metal in the wheel mixed

with the spark stream of the metal being tested. This

can confuse you and prevent you from properly

identifying the metal. Dress the wheel before you

begin spark testing and before each new test of a

different metal.

To do a spark test, hold a sample of the material

against a grinding wheel. The sparks given off, or the

lack of sparks, help you identify the metal. Look for

the length of the spark stream, its color, and the type

of sparks.

Figure 3-2 shows the four fundamental spark

forms. View A shows shafts, buds, breaks, and

arrows. The arrow or spearhead is characteristic of

molybdenum, a metallic element of the chromium

group that resembles iron and is used to form

steel-like alloys with carbon. The swelling, or buds,

in the spark line indicate nickel with molybdenum.

Figure 3-2.--Fundamental spark forms.

View B shows shafts and sprigs, or sparklers, that

3-12