and file test. When you perform these tests, you

IDENTIFICATION OF METALS

should compare the unknown metal with a known

sample of some metal. You also will need good

The various base metals, such as iron, copper,

lighting, a strong permanent magnet, and access to a

lead, zinc, and aluminum have certain identifying

lathe. A word of caution: when you perform these

characteristics, such as surface appearance and

tests, DO NOT be satisfied with the results of only

weight. This helps persons who work with or handle

one test. Use as many tests as possible so you can

these materials to distinguish one from another.

increase the chances of an accurate identification.

There are, however, a number of related alloys that

resemble each other and their base metal so closely

that they defy accurate identification by simple

Spark Test

means. You may have to send these metals to a

shipyard for analysis.

There are other means of rapid identification of

Spark testing is the identification of a metal by

observing the color, size, and shape of the spark

metals. These methods, however, do not provide

stream given off when you hold the metal against a

positive identification and should not be used in

grinding wheel. This method of identification is

critical situations where a specific metal is required.

adequate for most machine shop purposes. When you

Some of the methods that we'll discuss here are

must know the exact composition of a metal, make a

magnet tests, chip tests, file tests, acid reaction tests,

and spark tests. The latter two are most commonly

chemical analysis. You need a lot of experience

used by the Navy and we'll discuss them in more

before you can identifiy metals by a spark test. To

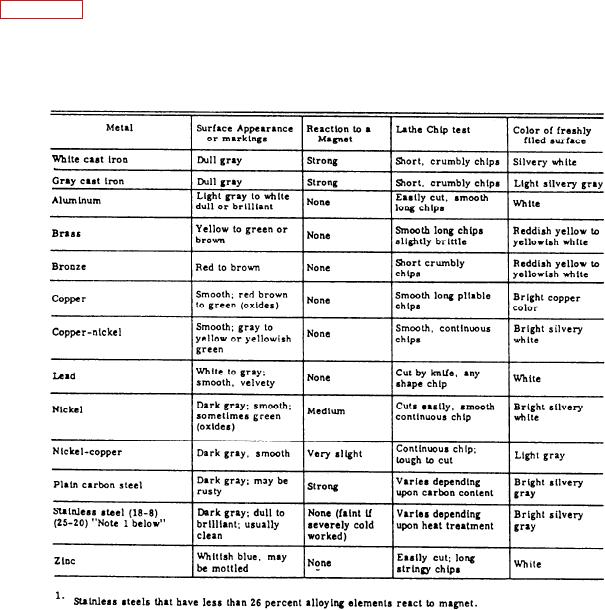

detail. Table 3-3 contains information related to

gain this experience, you'll need to practice by

surface appearance, magnetic reaction, lathe chip test,

comparing the spark stream of unknown specimens

Table 3-3.--Rapid Identification of Metals

3-11