28.194

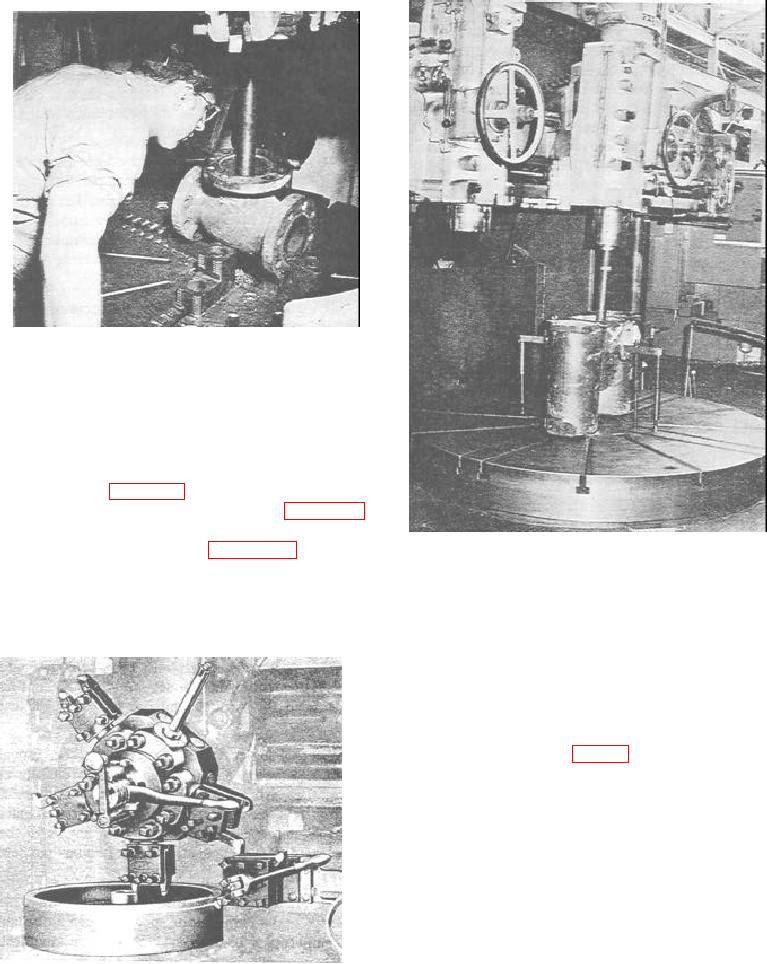

Figure 8-3.--Refacing a valve seat in a vertical turret lathe.

production work. For example, you can mount a large

valve on the horizontal face of its worktable or chuck

easier than on almost any other type of machine. For

other examples, figure 8-3 shows a typical valve seat

refacing job on a vertical turret lathe; figure 8-4

shows the double tooling principle applied to a

machining operation, and figure 8-5 shows a

straight boring bar used to bore a large saltwater

28.461

strainer body.

Figure 8-5.--Straight boring bar being used to bore a large

saltwater strainer.

TAPER TURNING

The following information is based on a Bullard

vertical turret lathe. (See fig. 8-1.)

There are several ways to cut a taper on a

vertical turret lathe. You can cut a 45 taper with

either a main turret-held cutter or a side head-held

cutter if you engage the vertical and horizontal

feeds simultaneously. To cut a taper of less than

30 with a main turret-held tool, set the turret slide

for the correct degree of taper and use only the

vertical feed for the slide. If you did this operation

on an engine lathe, you would use the compound

rest and advance the cutter by manual feed. On a

28.195

vertical lathe, you would USC the vertical power

Figure 8-4.--Double tooling.

feed.

8-4