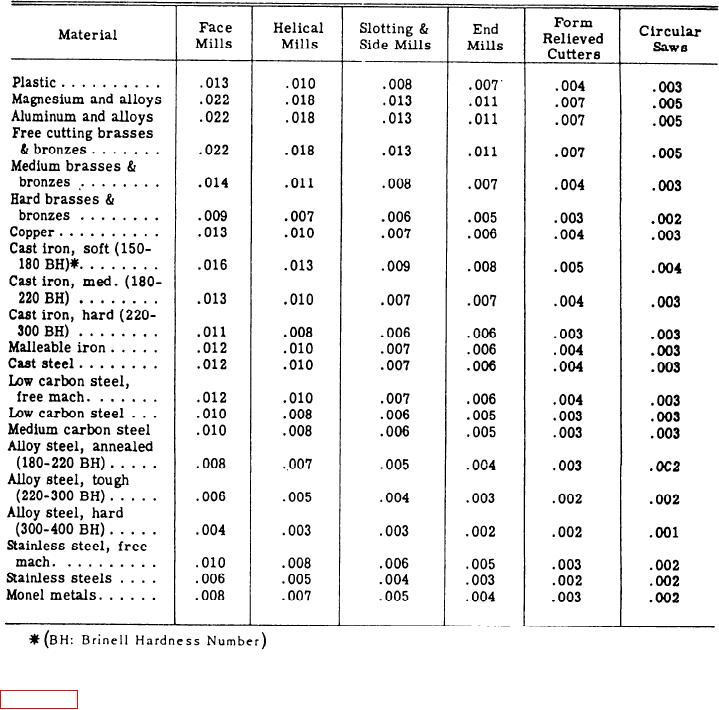

Table 7-4.--Recommended Chip Loads

Table 7-4 shows recommended chip loads for

There are a number of synthetic coolants. Follow

milling various materials with various types of

the manufacturer's recommendations when mixing

high-speed steel cutters.

them. If a synthetic coolant is not available, you can

use soluble oil mixed at the rate of 40 parts water to 1

part oil.

The purpose of a cutting coolant is to reduce

When using a periphery milling cutter, apply the

frictional heat and thereby extend the life of the

coolant to the point at which the tooth leaves the

cutter's edge. Coolant also lubricates the cutter face

work. This will allow the tooth to cool before you

and flushes away the chips, reducing the possibility of

begin the next cut. Allow the coolant to flow freely

damage to the finish.

on the work and cutter.

7-52