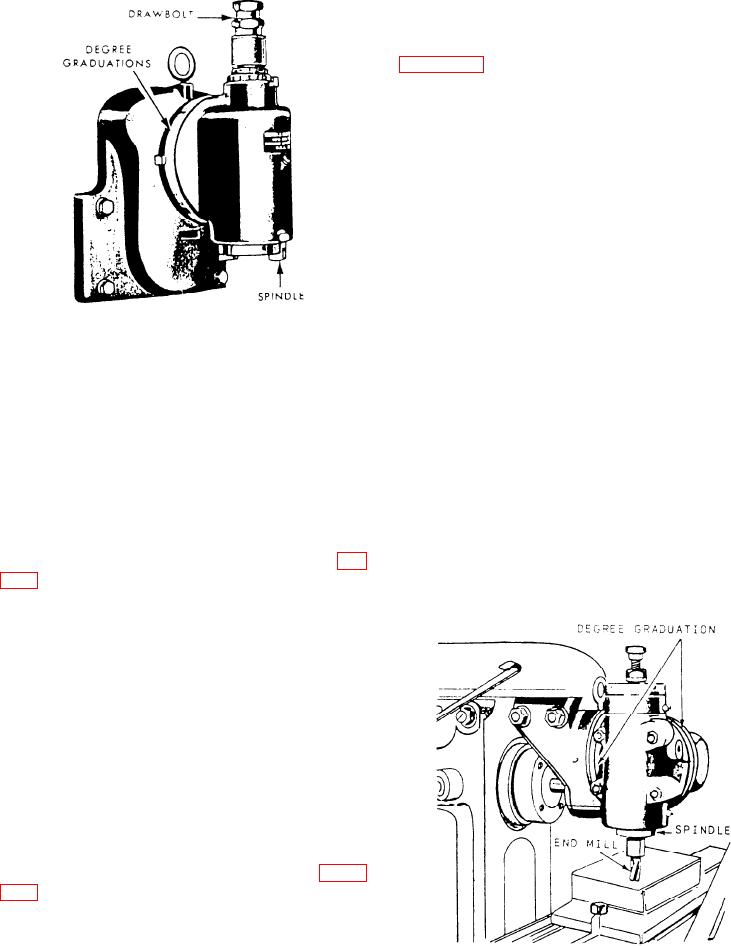

RACK MILLING ATTACHMENT

The rack milling attachment, shown in

figure 7-81, is used primarily to cut teeth on racks,

although it can be used for other operations. The

cutter is mounted on a spindle that extends through

the attachment parallel to the table T-slots. An

indexing arrangement is used to space the rack teeth

quickly and accurately.

FEEDS, SPEEDS, AND COOLANTS

Milling machines usually have a spindle speed

range from 25 to 2,000 rpm and a feed range from

1/4 inch to 30 inches per minute (ipm). The feed is

independent of the spindle speed; therefore, you can

Figure 7-79.--Vertical milling attachment.

feed a workpiece at any rate available in the feed

range regardless of the spindle speed. In the following

paragraphs, we'll discuss some of the factors

the attachment and then set by the two rotary swivels

concerning the selection of appropriate milling feeds

so the cutter will cut at any angle to the horizontal or

and speeds.

the vertical plane. The spindle of the attachment is

driven by gearing connected to the milling machine

SPEEDS

spindle.

Heat generated by friction between the cutter and

VERTICAL MILLING ATTACHMENT

the work may be regulated by the use of proper speed,

feed, and cutting coolant. Regulation of this heat is

You can use a vertical milling attachment (fig.

7-79) to convert the horizontal spindle machine to a

vertical spindle machine and swivel the cutter to any

position in the vertical plane. You can use a universal

milling attachment to swivel the cutter to any position

in both the vertical and horizontal planes. These

attachments will help simplify otherwise complex

jobs.

HIGH-SPEED UNIVERSAL ATTACHMENT

You can use a high-speed universal attachment to

perform milling operations at higher speeds than

those for which the machine was designed. This

attachment is clamped to the machine and driven by

the milling machine spindle, as you can see in figure

7-80. You can swivel the attachment spindle head and

cutter 360 in both planes. The attachment spindle is

driven at a higher speed than the machine spindle.

You must consider the ratio between the rpm of the

two spindles when you calculate cutter speed. Drive

Figure 7-80.--High-speed universal milling attachment.

small cutters, end mills, and drills at high rates of

speed to maintain an efficient cutting action.

7-48