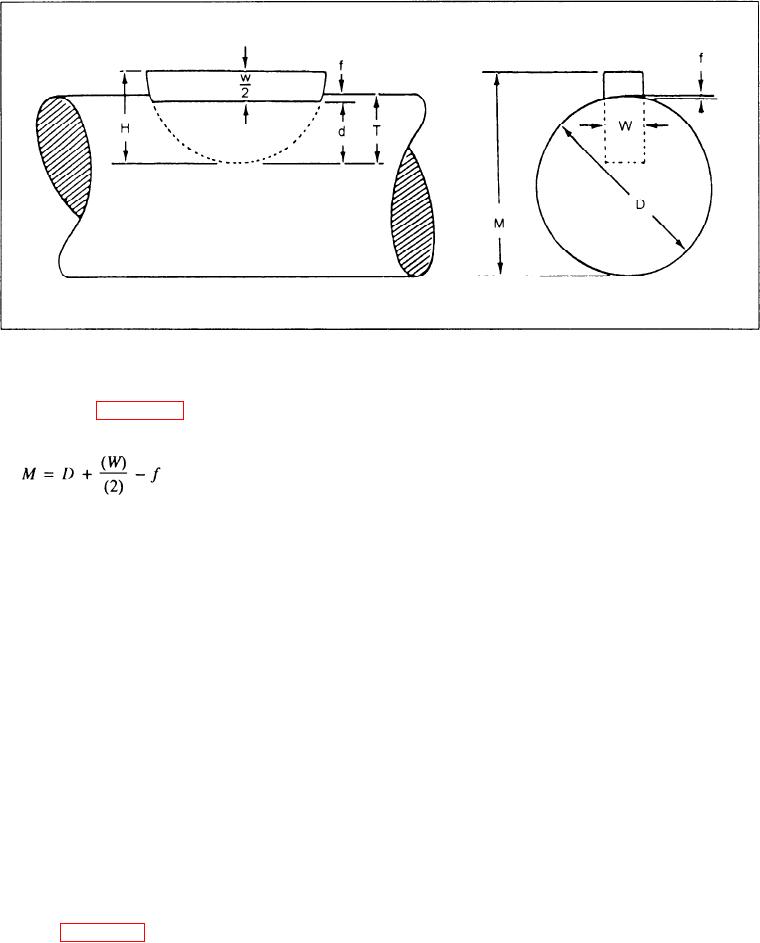

Figure 7-75--Dimensions for a Woodruff keyseat.

distance, M in figure 7-75. You can also determine

distance M by using the formula:

you can do very efficiently on a milling machine. The

graduated feed screws make it possible to accurately

locate the work in relation to the cutting tool. In each

where

operation the cutting tool is held and rotated by the

spindle, and the work is fed into the cutting tool.

M = micrometer reading

Drilling and Reaming

D = diameter of the shaft

height of the arc between the top of the

Use the same drills and reamers that you use to

f = slot and the top of the shaft

drill and ream in the lathe and the drill press. Hold

drills and reamers in the spindle by the same methods

NOTE: Tables in some references may differ

that you use to hold straight and taper-shanked end

slightly from the above calculation for the value M,

mills. You can hold the work in a vise, clamped to the

due to greater allowance for clearance at the top of the

table, held in fixtures or between centers, and in index

key.

head chucks, as you do in milling. Determine the

speeds used to drill and ream in the same manner as

FLY CUTTING

you did those used to drill and ream in the lathe or the

drill press. Feed the work into the drill or reamer by

You will use a fly cutter when a formed cutter is

either hand or power feed. If you mount the cutting

required but not available. Fly cutters are high-speed

tool in a horizontal position, use the transverse or

steel tool blanks that have been ground to the required

saddle feed. If you mount a drill or reamer in a

shape. Any shape can be ground on the tool if the

vertical position, as in a vertical-type machine, use the

cutting edges arc given enough clearance. Fly cutters

vertical feed.

are mounted in fly cutter arbors, such as the one

shown in figure 7-45. Use a slow feed and a shallow

Boring

depth of cut to prevent breaking the tool. It is a good

idea to rough out as much excess material as possible

Of the three operations, boring is the only one that

with ordinary cutters and to use the fly cutter to finish

warrants special treatment. On a milling machine you

shaping the surface.

7-45