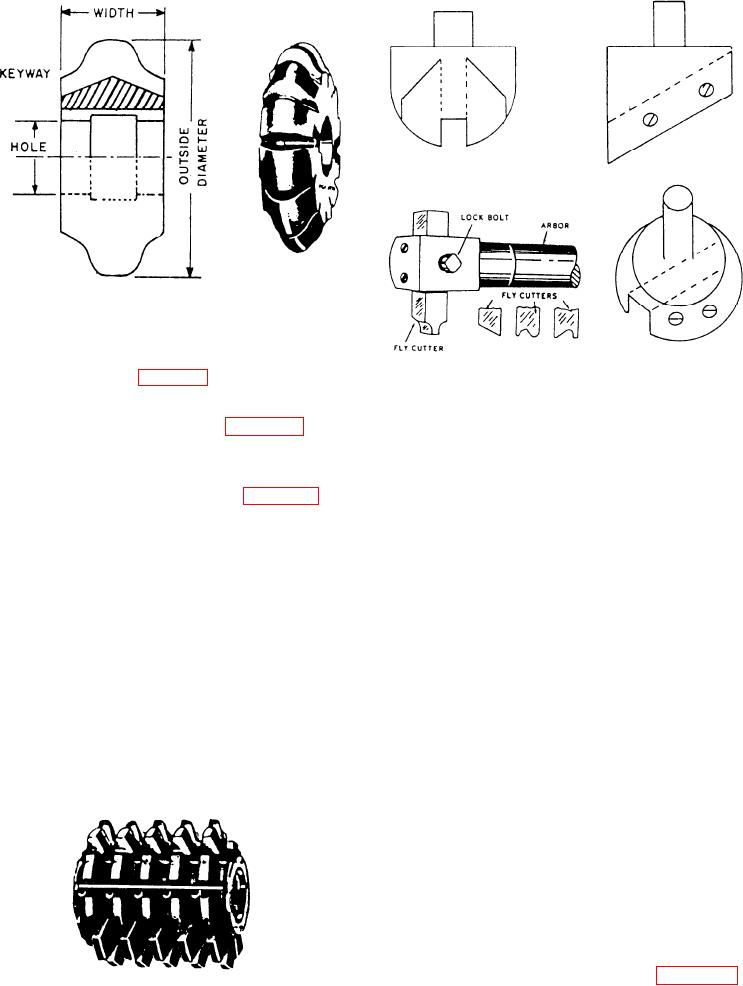

Figure 7-43.--Sprocket wheel cutter.

SPROCKET WHEEL CUTTER. --The

sprocket wheel cutter (fig. 7-43) is a formed cutter

Figure 7-45.--Fly cutter arbor and fly cutters.

that is used to mill teeth on sprocket wheels.

GEAR HOB.--The gear hob (fig. 7-44) is a

Selection

formed milling cutter with teeth cut like threads on a

screw.

Each cutter can do one kind of job better than any

other cutter in a given situation. A cutter may or may

FLY CUTTER.--The fly cutter (fig. 7-45) is

not be limited to a specific milling operation. To

often manufactured locally. It is a single-point cutting

select the most suitable cutter for a particular

tool similar in shape to a lathe or shaper tool. It is

operation, you must consider the kind of cut to be

held and rotated by a fly cutter arbor. There will be

made, the material to be cut, the number of parts to be

times when you need a special formed cutter for a

machined, and the type of milling machine available.

very limited number of cutting or boring operations.

This will probably be the type of cutter you will use

Another factor that affects a milling operation is

since you can grind it to almost any form you need.

the number of teeth in the cutter. If there are too many

We have discussed a number of the more common

teeth, the space between them is so small that it

types of milling machine cutters. For a more detailed

prevents the free flow of chips. The chip space

discussion of these, other types, and their uses,

should also be smooth and free of sharp corners to

consult the Machinery's Handbook, machinist

prevent the chips from clogging the space. A

publications, or the applicable technical manual. We

coarse-tooth cutter is more satisfactory for milling

will now discuss the selection of cutters.

material that produces a continuous and curled chip.

The coarse teeth not only permit an easier flow of

chips and coolant but also help to eliminate chatter. A

fine-tooth cutter is more satisfactory for milling a thin

material. It reduces cutter and workpiece vibration

and the tendency for the cutter teeth to "straddle" the

work and dig in.

Another factor you should consider in selecting a

cutter is its diameter. Select the smallest diameter

cutter that will allow the arbor to pass over the work

without interference when you take the cut. Figure 7-46

shows that a small cutter takes a cut in less time than

Figure 7-44.--Gear hob.

a larger cutter.

7-26