angle of 90 to the cutter axis and the other usually at

45, 50, or 80.

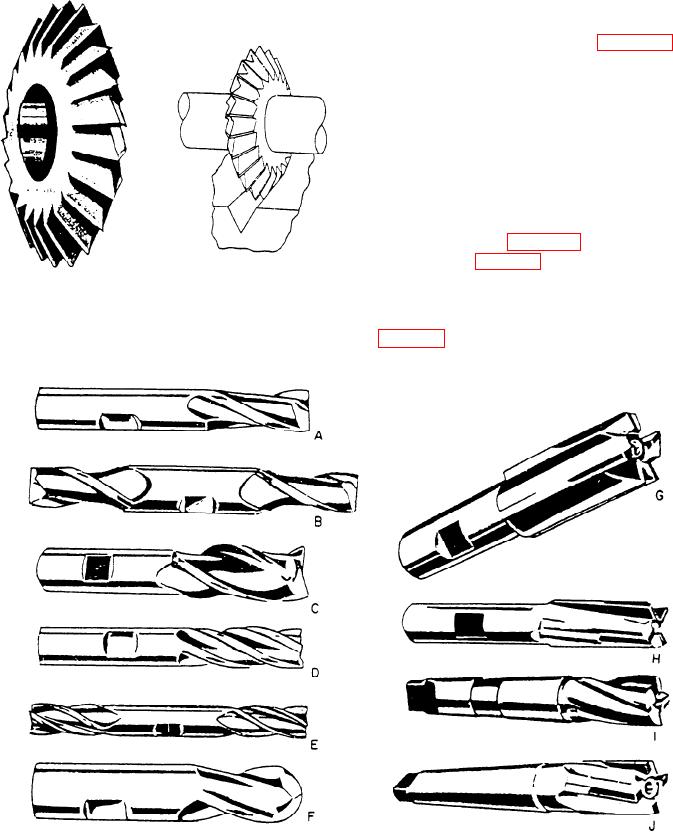

The double-angle cutter (fig. 7-32) has two

cutting faces, which are at an angle to the cutter axis.

When both faces are at the same angle to the axis, you

obtain the cutter you want by specifying the included

angle. When they are different angles, you specify

the angle of each side with respect to the plane of

intersection.

END MILL CUTTERS.--End mill cutters may

be the SOLID TYPE with the teeth and the shank as

an integral part (fig. 7-33), or they may be the

SHELL TYPE (fig. 7-34) in which the cutter body and

the shank or arbor are separate. End mill cutters have

Figure 7-32.--Double-angle cutter.

teeth on the circumference and on the end. Those on

the circumference may be either straight or helical

A. Two-flute single-end

Two-flute ball-end

F.

B. Two-flute double-end

G.

Carbide-tipped, straight flutes

C. Three-flute single-end

H.

Carbide-tipped, right-hand helical flutes

D. Multiple-flute singleend

I.

Multiple-flute with taper shank

E. Four-flute double-end

J.

Carbide-tipped with taper shank and helical flutes

Figure 7-33.--End mill cutters.

7-22