machine spindle taper of 3 1/2 inches per foot. The

largest diameter of the taper is identified by a number.

For example, the large diameter of a No. 40 milling

machine spindle taper is 1 3/4 inches. The following

numbers represent common milling machine spindle

tapers and their sizes:

Large Diameter

Number

10

5/8 inch

20

7/8 inch

1/4 inch

30

1 3/4 inches

40

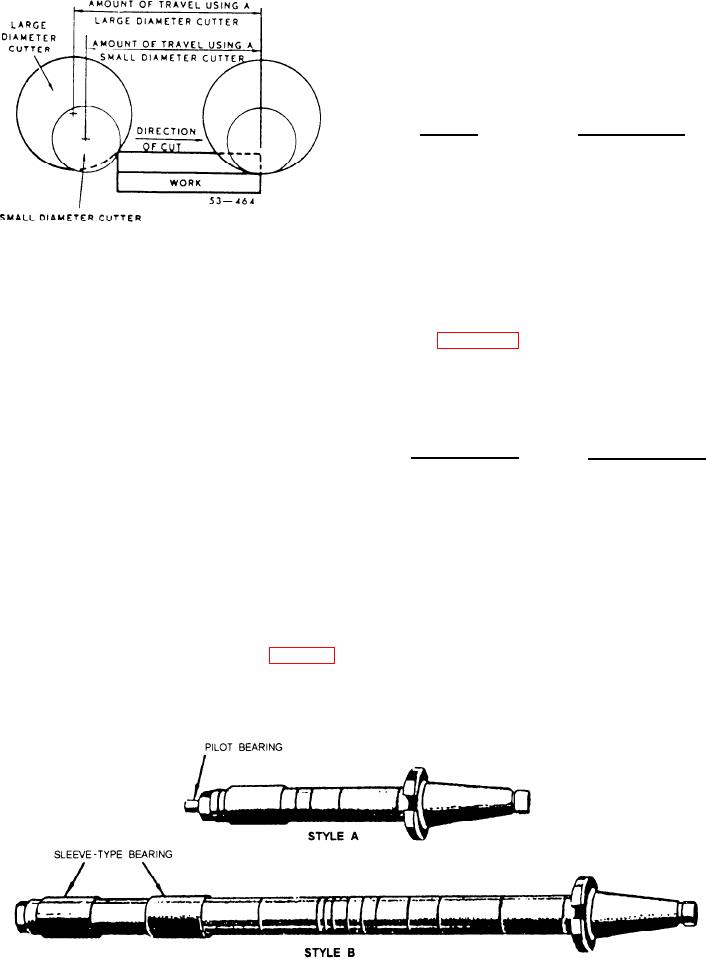

Figure 7-46.--Cutter diameter selection.

2 3/4 inches

50

4 1/4 inches

60

ARBORS

Standard arbors are available in styles A and B, as

shown in figure 7-47. Style A arbors have a pilot-type

You can mount milling machine cutters on several

bearing usually 1 1/32 inch in diameter. Style B arbors

types of holding devices. You must know the devices

have a sleeve-type outboard bearing. Numerals

and the purpose of each of them to make the most

identify the outside diameter of the bearing sleeves, as

suitable tooling setup for the operation. We will cover

follows:

the various types of arbors and the mounting and

dismounting of arbors in this section.

Sleeve Number

Outside Diameter

NOTE: Technically, an arbor is a shaft on which

3

1 7/8 inches

a cutter is mounted. For convenience, since there are

4

2 1/8 inches

so few types of cutter holders that are not arbors, we

will refer to all types of cutter holding devices as

5

2 3/4 inches

arbors.

The inside diameter can be any one of several

standard diameters that are used for the arbor shaft.

Standard Arbor

Style A arbors sometimes have a sleeve bearing

There are several types of milling machine arbors.

that permits the arbor to be used as either a style A or

You will use the common or standard types (fig. 7-47)

a style B arbor. A code system, consisting of

to hold and drive cutters that have mounting holes.

numerals and a letter, identifies the size and style of

One end of the arbor usually has a standard milling

the arbor. The code number is stamped into the flange

Figure 7-47.--Standard milling machine arbors.

7-27