These mills may be either the single-end type with the

cutter on one end only, or they may be the double-end

type. (See fig. 7-33.)

MULTIPLE-FLUTE END MILLS have three,

four, six, or eight flutes and normally are available in

diameters up to 2 inches. They may be either the

single-end or the double-end type (fig. 7-33).

BALL END MILLS (fig. 7-33) are used to mill

fillets or slots with a radius bottom, to round pockets

and the bottom of holes, and for all-around die sinking

and die making work. Two-flute end mills with end

cutting lips can be used to drill the initial hole as well

as to feed longitudinally. Four-flute ball end mills

with center cutting lips also are available. These

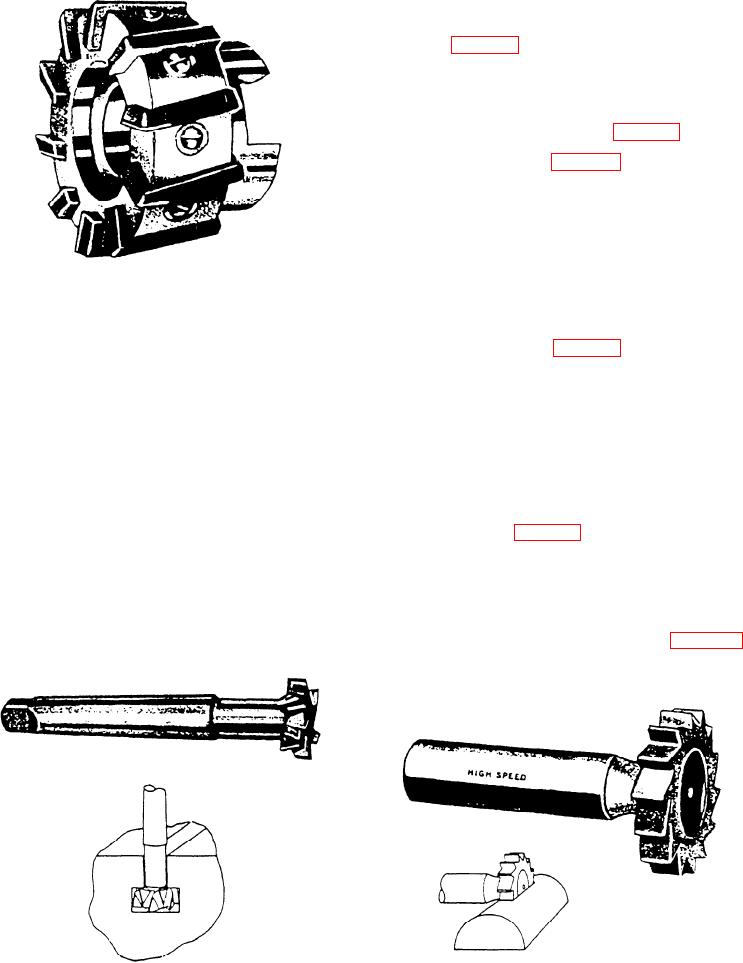

Figure 7-36.--Inserted tooth face milling cutter.

work well for tracer milling, fillet milling, and die

sinking.

mill cutters. Common operations include the milling

SHELL END MILLS (fig. 7-34) have a hole used

of slots, keyways, pockets, shoulders, and flat

to mount the cutter on a short (stub) arbor. The center

surfaces, and the profiling of narrow surfaces.

of the shell is recessed for the screw or nut that fastens

the cutter to the arbor. These mills are made in larger

End mill cutters are used most often on vertical

sizes than solid end mills, normally in diameters from

milling machines. However, they also are used

1/4 to 6 inches. Cutters of this type are intended for

frequently on machines with horizontal spindles.

slabbing or surfacing cuts, either face milling or end

Many different types of end mill cutters are available

milling, and usually have helical teeth.

in sizes ranging from 1/64 inch to 2 inches. They may

FACE MILLING CUTTER.--Inserted tooth

be made of high-speed steel, have cemented carbide

face milling cutters (fig. 7-36) are similar to shell end

teeth, or be of the solid carbide type.

mills in that they have teeth on the circumference and

TWO-FLUTE END MILLS have only two teeth

on the end. They are attached directly to the spindle

on their circumference. The end teeth can cut to the

nose and use inserted, replaceable teeth made of

center. Hence, they may be fed into the work like a

carbide or any alloy steel.

drill; they can then be fed lengthwise to form a slot.

T-SLOT CUTTER.--The T-slot cutter (fig. 7-37)

is a small plain milling cutter with a shank. It is

Figure 7-38.--Woodruff keyseat cutter.

Figure 7-37.--T-slot cutter.

7-24