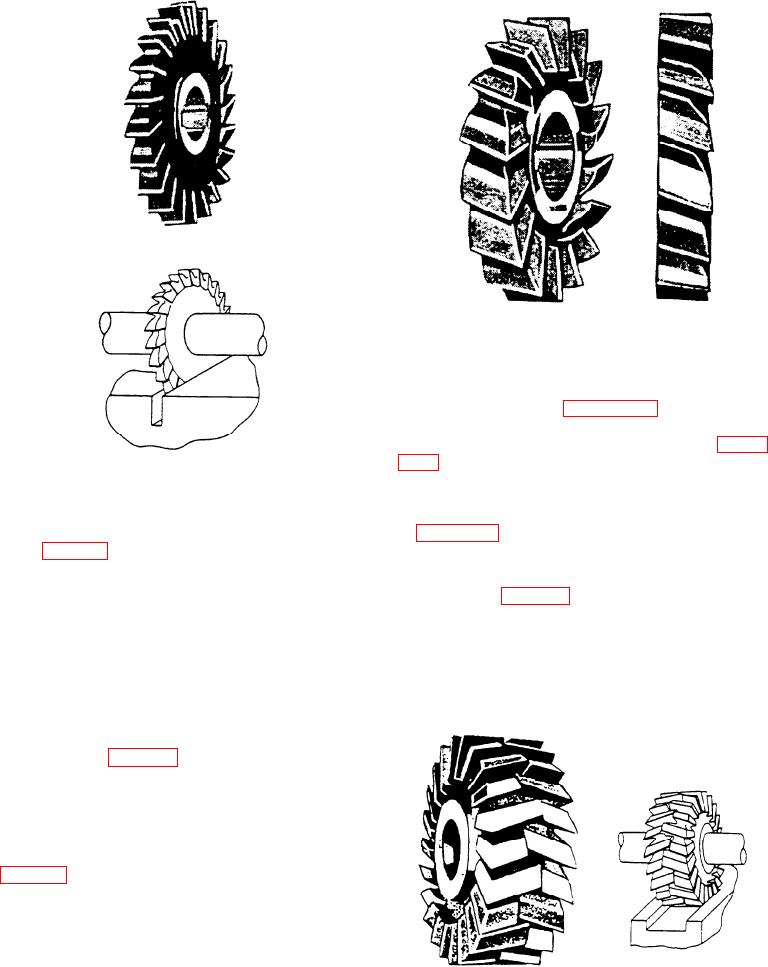

Figure 7-25.--Half-side milling cutter.

center than at the outer edge to give proper clearance

for milling deep slots. Figure 7-27 shows a metal

slitting saw with teeth cut in the circumference of the

cutter only. Some saws, such as the one in figure

7-28, have side teeth that achieve better cutting

action, break up chips, and prevent dragging when

Figure 7-24.--Side milling cutter.

you cut deep slots. For heavy sawing in steel, there

are metal slitting saws with staggered teeth, as shown

SIDE MILLING CUTTER.--The side milling

in figure 7-29. These cutters are usually 3/16 inch to

cutter (fig. 7-24) is a plain milling cutter with teeth cut

3/8 inch thick

on both sides as well as on the periphery or

SCREW SLOTTING CUTTER.--The screw

circumference of the cutter. You can see that the

slotting cutter (fig. 7-30) is used to cut shallow slots,

portion of the cutter between the hub and the side of

such as those in screwheads. This cutter has fine teeth

the teeth is thinner to give more chip clearance. These

cut on its circumference. It is made in various

cutters are often used in pairs to mill parallel sides.

thicknesses to correspond to American Standard

This process is called straddle milling. Cutters more

gauge wire numbers.

than 8 inches in diameter are usually made with

inserted teeth. The size designation is the same as for

plain milling cutters.

HALF-SIDE MILLING CUTTER.--Half-side

milling cutters (fig. 7-25) are made particularly for

jobs where only one side of the cutter is needed.

These cutters have coarse, helical teeth on one side

only so that heavy cuts can be made with ease.

SIDE MILLING CUTTER (INTERLOCK-

ING).--Side milling cutters whose teeth interlock

(fig. 7-26) can be used to mill standard size slots. The

width is regulated by thin washers inserted between

the cutters.

METAL SLITTING SAW.--You can use a

metal slitting saw to cut off work or to mill narrow

slots. A metal slitting saw is similar to a plain or side

milling cutter, with a face width usually less than 3/16

inch. This type of cutter usually has more teeth for a

Figure 7-26.--Interlocking teeth side milling cutter.

given diameter than a plain cutter. It is thinner at the

7-20