Milling cutters generally take their names from

from the one in which the pin is inserted, considering

the operation they perform. The most common

this hole as zero. Then, use the index sector and you

cutters are (1) plain milling cutters of various widths

will not need to count the holes for each division.

and diameters, used principally for milling flat

When using the index crank to revolve the spindle,

surfaces that are parallel to the axis of the cutter; (2)

you must unlock the spindle clamp screw. However,

angular milling cutters used to mill V-grooves and the

before you cut work held in or on the index head, lock

the spindle again to relieve the strain on the index pin.

grooves in reamers, taps, and milling cutters; (3) face

milling cutters used to mill flat surfaces at a right

angle to the axis of the cutter; and (4) forming cutters

CUTTERS AND ARBORS

used to produce surfaces with an irregular outline.

When you perform a milling operation, you move

Milling cutters may also be classified as

the work into a rotating cutter. On most milling

arbor-mounted, or shank-mounted. Arbor-mounted

machines, the cutter is mounted on an arbor that is

cutters are mounted on the straight shanks of arbors.

driven by the spindle. However, the spindle may

The arbor is then inserted into the milling machine

drive the cutter directly. We will discuss cutters in the

spindle. We'll discuss the methods of mounting

first part of this section and arbors in the second part.

arbors and cutters in greater detail later in this chapter.

Milling cutters may have straight, right-hand,

CUTTERS

left-hand, or staggered teeth. Straight teeth are

parallel to the axis of the cutter. If the helix angle

There are many different milling machine cutters.

twists in a clockwise direction (viewed from either

Some can be used for several operations, while others

end), the cutter has right-hand teeth. If the helix angle

can be used for only one. Some have straight teeth

twists in a counterclockwise direction, the cutter has

and others have helical teeth. Some have mounting

left-hand teeth. The teeth on staggered-tooth cutters

shanks and others have mounting holes. You must

are alternately left-hand and right-hand.

decide which cutter to use. To do so, you must be

familiar with the various milling cutters and their

Types and Uses

uses. The information in this section will help you to

select the proper cutter for each of the various

There are many different types of milling cutters.

operations you will perform. In this section we will

We will discuss these types and their uses in the

cover cutter types and cutter selection.

following sections.

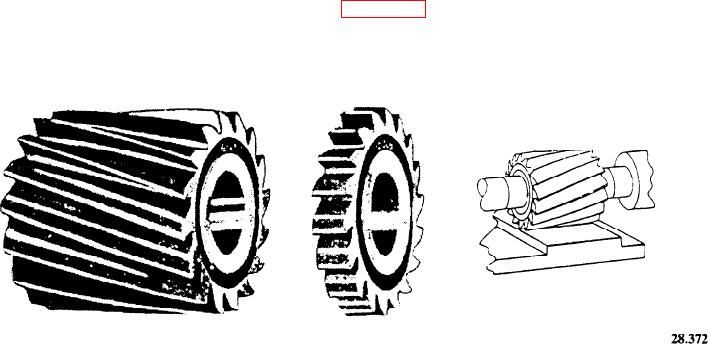

PLAIN MILLING CUTTER.--You will use

Standard milling cutters are made in many shapes

plain milling cutters to mill flat surfaces that are

and sizes for milling both regular and irregular

shapes. Various cutters designed for specific

parallel to the cutter axis. As you can see in

figure 7-22, a plain milling cutter is a cylinder with

purposes also are available; for example, a cutter for

teeth cut on the circumference only. Plain milling

milling a particular kind of curve on some intermediate

part of the workpiece.

cutters are made in a variety of diameters and widths.

Figure 7-22.--Plain milling cutters.

7-18