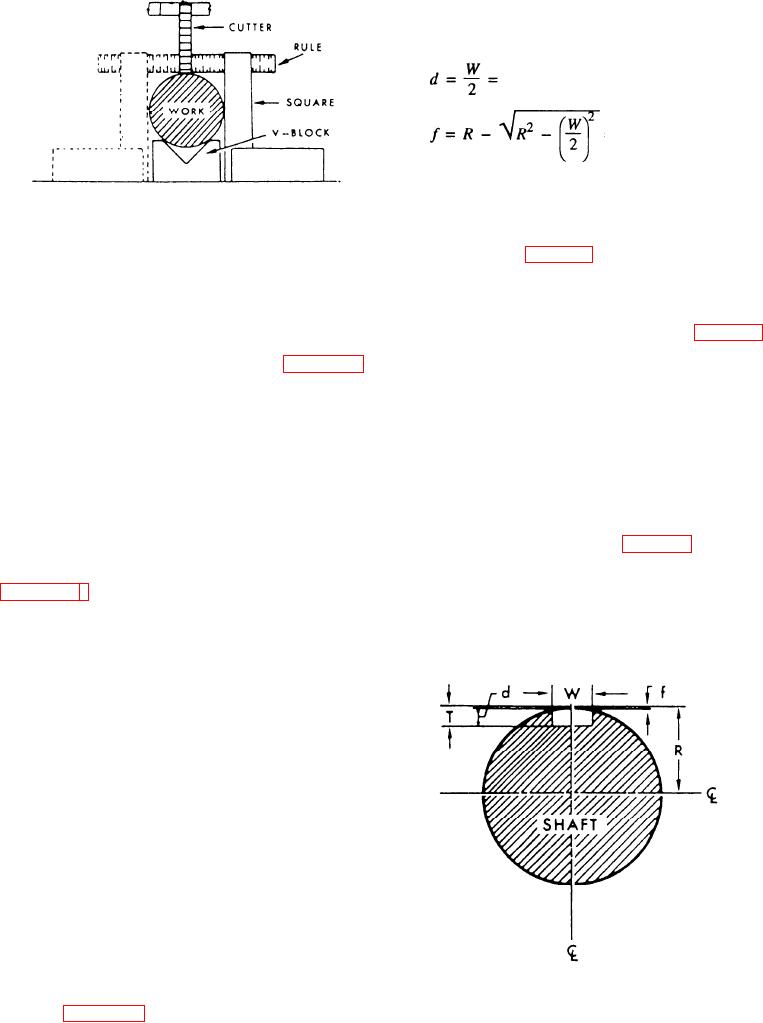

Total depth of cut (T) = d + f

where

depth of the keyseat

= height of arc

W = width of the key

R = radius of the shaft

Figure 7-71.--Visual alignment of a cutter.

The height of arc (f) for various sizes of shafts and

keys is shown in table 7-1. Keyseat dimensions for

mill. Then, move the work a distance equal to the

rounded end and rectangular keys are contained in the

radius of the work plus the radius of the end mill.

Machinery's Handbook. Check the keyseats for

This will center the mill over the center line of the

accuracy with rules, outside and depth micrometers,

keyseat. Move the work up, using hand feed, until a

vernier calipers, and go-no-go gauges. Use table 7-1

piece of paper held between the work and the bottom

for both square and Woodruff keyseats, which will be

of the end mill begins to tear, as shown in figure 7-70,

explained next.

B. Then, move the table and work away from the

WOODRUFF KEYSEAT.--A Woodruff key is a

bottom of the end mill. Set and lock the graduated

small half-disk of metal. The rounded portion of the

dial at ZERO on the vertical feed, and then feed up for

key fits in the slot in the shaft. The upper potion fits

the roughing cut. You can determine the cutter rpm

into a slot in a mating part, such as a pulley or gear.

and the longitudinal feed in the same manner as you

You align the work with the cutter and measure the

do for conventional milling cutters. The higher

width of the cut in exactly the same manner as you do

speeds and feeds generate more heat, so flood the

to mill straight external keyseats.

work and the cutter with coolant.

A Woodruff keyseat cutter (fig. 7-73) has deep

When extreme accuracy is not required, you can

flutes cut across the cylindrical surface of the teeth.

align the work with the cutter visually, as shown in

The cutter is slightly thicker at the crest of the teeth

figure 7-7 1. Position the work by eye as near as

than it is at the center. This feature provides clearance

possible to the midpoint of the cutter. Make the final

between the sides of the slot and the cutter. Cutters

alignment by moving the work in or out a slight

amount, as needed. The cutter should be at the exact

center of the work diameter measurement of the steel

rule. You can use this method with both plain milling

cutters and end mills.

Before you begin to machine the keyseat, you

should measure the width of the cut. You cannot be

certain that the width will be the same as the thickness

of the cutter. The cutter may not run exactly true on

the arbor or the arbor may not run exactly true on the

spindle. The recommended practice is to nick the end

of the work with the cutter and then to measure the

width of the cut.

Specifications for the depth of cut are usually

Furnished. When they are not available, you can

determine the total depth of cut for a square keyseat

by using the following formula based on dimensions

Figure 7-72.--Keyseat dimensions for a straight square key.

shown in figure 7-72.

7-42