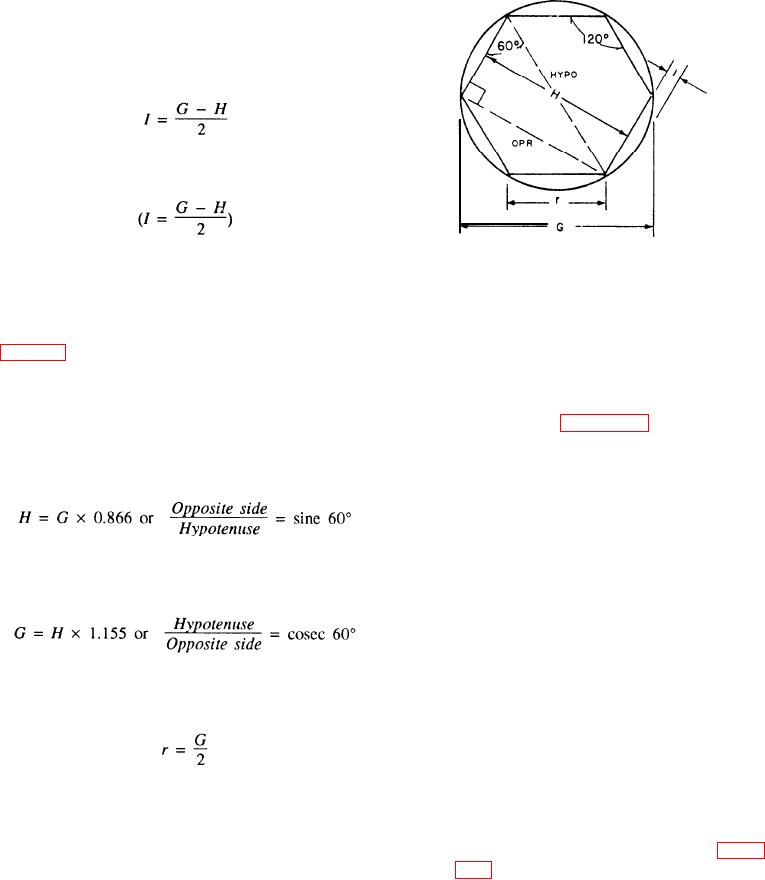

The amount of material that you must remove to

machine each side of the square is equal to one-half

the difference between the diameter of the stock and

the distance across the flats.

You use the same formula

Figure 7-65.--Diagram of a hexagon.

to determine the amount of material to remove when

you machine a hexagon.

The size of the largest hexagon that you can

NOTE: Because most index heads are quite

machine from a given size of round stock (H in

heavy and awkward, you should get someone to help

fig. 7-65) is equal to the diagonal (the diameter of the

you place the head on the milling machine table.

stock) of the hexagon times 0.866 or

After you have mounted the index head on the

Opposite side = Largest hexagon that can be

table, position the head spindle in the vertical

machined

position, as shown in figure 7-61. Use the degree

graduations on the swivel block. This is accurate

Hypotenuse = Diagonal or diameter of round

enough for most work requiring the use of the index

stock

head. The vertical position will allow you to feed the

work horizontally.

Then, tighten the work in the chuck to keep it

from turning due to the cutter's thrust. Install the

The diagonal of a hexagon equals the distance across

arbor, cutter, and arbor support. The cutter should be

the flats times 1.155, or

as close as practical to the column. Remember, this is

done so the setup will be more rigid. Set the machine

for the correct roughing speed and feed.

1. With the cutter turning, pick up the cut on the

end of the work.

The length of a flat is equal to one-half the length

of the diagonal,

2. Move the work sideways to clear the cutter.

3. Raise the knee a distance equal to the length

of the flat surfaces to be cut.

4. Move the table toward the revolving cutter

We will explain two methods used to machine a

and pick up the side of the work. Use a piece

square or hexagon: work mounted in a chuck and

of paper in the same manner as discussed

work mounted between centers.

earlier in this chapter and shown in figure

You can machine a square or hexagon on work

mounted in a chuck by using either a side milling

5. Set the cross-feed graduated dial at ZERO.

cutter or an end mill. We will discuss the side milling

cutter first. Before placing the index head on the

6 . Move the work clear of the cutter.

milling machine table, be sure the table and the

Remember, the cutter should rotate so the

bottom of the index head have been cleaned of all

cutting action takes place as in "up milling."

chips and other foreign matter. Spread a thin film of

clean machine oil over the area of the table to which

7. Feed the table in the required amount for a

the index head will be attached to prevent corrosion.

roughing cut.

7-37