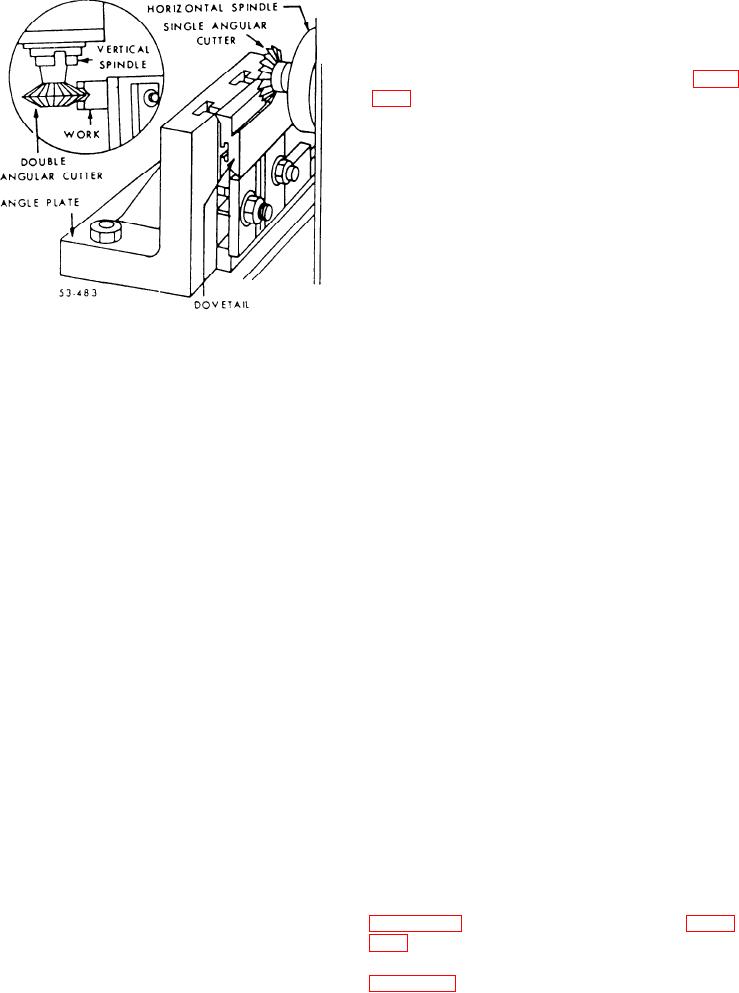

ANGULAR MILLING

Angular milling is the milling of a flat surface that

is at an angle to the axis of the cutter. Normally, you

will use an angular milling cutter, as shown in figure

7-60. However, you can perform angular milling with

a plain, side, or face milling cutter by positioning the

work at the required angle.

Many maintenance or repair tasks require you to

machine flat surfaces on cylindrical work. They

include milling squares and hexagons, and milling

two flats in the same plane.

A square or hexagon is milled on an object to

provide a positive drive, no slip area that can be

grasped by various tools, such as wrenches and

cranks. You will machine squares and hexagons

Figure 7-60.--Angular milling.

frequently on the ends of bolts, taps, reamers, or other

items that are turned by a wrench and on drive shafts

and other items that require a positive drive. The

11. Move the work away from the cutter with the

following information will help you to understand the

table and direct the coolant flow onto the

cutter.

machining of squares and hexagons.

12. Set the roughing depth of cut, using the

graduated dial, and lock the saddle.

Cutter Setup

13. Position the work to about 1/16 inch from the

cutter, and then engage the power feed.

The two types of cutters you will use most often

14. After completing the cut, stop the spindle,

to machine squares or hexagons are side and end

and move the work back to the starting point

milling cutters. You can use side milling cutters to

before the next cut.

machine work that is held in a chuck and for heavy

15. Set the speed and feed for the finishing cut,

cutting. You can use end mills for work that is held in

and then unlock the saddle.

a chuck or between centers and for light cutting. If

16. Move the saddle in for the final depth of cut

you use a side milling cutter, be sure the cutter

and relock it.

diameter is large enough so you can machine the full

length of the square or hexagon without interference

17. Engage the spindle and take the finish cut.

from the arbor. If you use an end mill, be sure it is

18. Stop the machine and return the work to the

slightly larger in diameter than the length of the

starting place.

square or hexagon. The cutter thrust for both types

19. Shut the machine off.

should be up when the work is mounted vertically and

down when it is mounted horizontally in order to use

20. Remove the work from the vise. Handle it

conventional (or up) milling.

very carefully to keep from cutting yourself

before you can deburr the work.

The reason for what appears to be a contradiction

21. Next, mount the work in the vise so the other

in the direction of thrust is the difference in the

end is ready to be machined. Mill this end in

direction of the feed. You can see this by comparing

the same manner as the first, but be sure to

figures 7-61 and 7-62. The cutter shown in figure

measure the length before you take the

7-61 rotates in a counterclockwise direction and the

finishing cut. Before removing the work

work is fed toward the left. The cutter shown in

from the vise, check it for accuracy and

figure 7-62 rotates in a clockwise direction and the

remove the burrs from the newly finished

end.

work is fed upward.

7-34