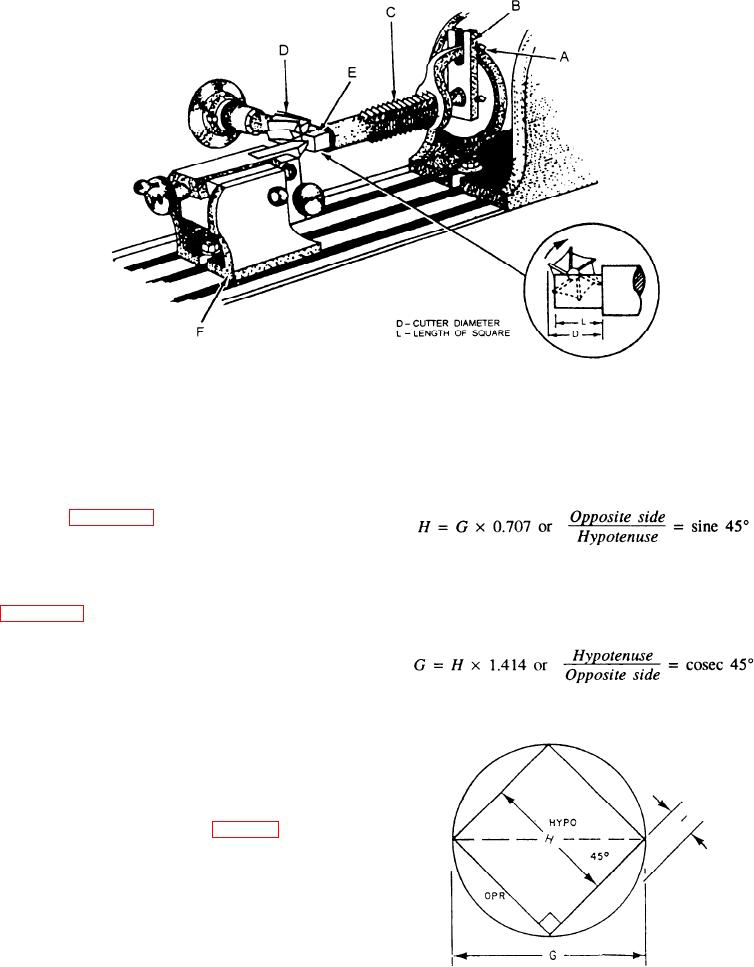

A. Lock screw for dog

D. End mill

B. Drive plate

E. Tap square

C. Tap

F. Footstock

Figure 7-63.--Milling a square using an end mill.

shown in figure 7-63, contains two lock screws. One

lock screw clamps the drive plate to the index center

and ensures that the drive plate moves with the index

spindle. The other lock screw clamps the tail of the

The diagonal of a square equals the distance

dog against the side of the drive plate slot, as shown in

across the flats times 1.414. This is expressed as

figure 7-63, A. This eliminates any movement of the

work during the machining operation.

Calculations

The following information will help you

determine the amount of material you must remove to

produce a square or a hexagon. You must calculate

the dimensions of the largest square or hexagon that

you can machine from a piece of stock.

The size of a square (H in fig. 7-64) is measured

across the flats. The largest square that you can cut

from a given size of round stock equals the diameter

of the stock in inches (which is also the diagonal of

the square) times 0.707. This may be expressed as:

Opposite side = Side of a square

Hypotenuse = Diagonal of square

Figure 7-64.--Diagram of a square.

45 = 90 bisected

7-36