KNEE: The knee is the casting that supports the

position this lever to the left, to the right, or in the

table and the saddle. The feed change gearing is

center. Place the end of the lever to the left to feed the

enclosed within the knee. It is supported and is

table toward the left. Place it to the right to feed the

adjusted by turning the elevating screw. The knee is

table toward the right. Place it in the center to

fastened to the column by dovetail ways. You can

disengage the power feed or to feed the table by hand.

raise or lower the knee by either hand or power feed.

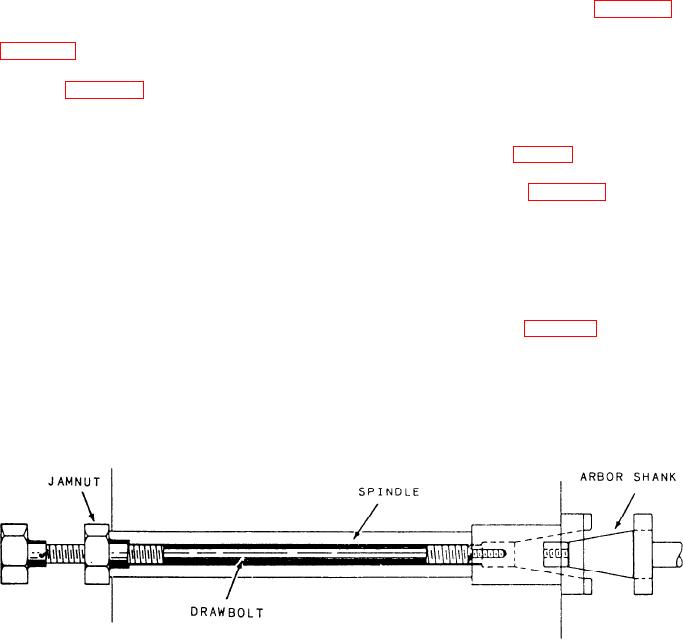

SPINDLE: The spindle holds and drives the

You usually use hand feed to take the depth of cut or

various cutting tools. It is a shaft mounted on bearings

to position the work and power feed to move the work

during the operation.

supported by the column. The spindle is driven by an

electric motor through a train of gears, all mounted

SADDLE and SWIVEL TABLE: The saddle

within the column. The front end of the spindle,

slides on a horizontal dovetail (which is parallel to the

which is near the table, has an internal taper machined

axis of the spindle) on the knee. The swivel table (on

in it. The internal taper (3 1/2 inches per foot) permits

universal machines only) is attached to the saddle and

you to mount tapered-shank cutter holders and cutter

can be swiveled approximately 45 in either direction.

arbors. Two keys, located on the face of the spindle,

provide a positive drive for the cutter holder, or arbor.

POWER FEED MECHANISM: The power feed

You secure the holder, or arbor, in the spindle by a

mechanism is contained in the knee and controls the

drawbolt and jamnut, as shown in figure 7-7. Large

longitudinal, transverse (in and out), and vertical

face mills are sometimes mounted directly to the

feeds. To set the rate of feed on machines, like the

spindle nose.

one in figure 7-5, position the feed selection levers as

indicated on the feed selection plate. On machines

like the one in figure 7-6, turn the speed selection

OVERARM: The overarm is the horizontal beam

handle until the desired rate of feed is indicated on the

to which you fasten the arbor support. The overarm

feed dial. Most milling machines have a rapid

may be a single casting that slides in dovetail ways on

traverse lever that you can engage when you want to

the top of the column (fig. 7-5) or it may consist of

temporarily increase the speed of the longitudinal,

one or two cylindrical bars that slide through holes in

transverse, or vertical feeds. For example, you would

the column, as shown in figure 7-6. To position the

engage this lever to position or align the work.

overarm on some machines, first unclamp locknuts

and then extend the overarm by turning a crank. On

NOTE: For safety reasons, you must use extreme

others, move the overarm by simply pushing on it.

caution whenever you use the rapid traverse controls.

You should extend the overarm only far enough to

TABLE: The table is the rectangular casting

position the arbor support to make the setup as rigid as

located on top of the saddle. It contains several T-slots

possible. To place arbor supports on an overarm such

in which you can fasten work or workholding devices.

as the one shown as B in figure 7-6, extend one of the

You can move the table by hand or by power. To

bars approximately 1 inch farther than the other bar.

move it by hand, engage and turn the longitudinal

Tighten the locknuts after you position the overarm.

handcrank. To move it by power, engage the

On some milling machines the coolant supply nozzle

longitudinal directional feed control lever. You can

is fastened to the overarm. You can mount the nozzle

Figure 7-7.--Spindle drawbolt.

7-5