However, small arbor supports can provide support

only at the extreme end of the arbor. For this reason

they are not recommended for general use. Large

arbor supports can provide support near the cutter, if

necessary.

NOTE: Before loosening or tightening the arbor

nut, you must install the arbor support. This will

prevent bending or springing of the arbor.

MACHINE DESIGNATION: All milling machines

are identified by four basic factors: size, horsepower,

model, and type. The size of a milling machine is

based on the longitudinal (from left to right) table

Figure 7-9.--Right-angle plate.

travel in inches. Vertical, cross, and longitudinal

travel are all closely related as far as overall capacity

is concerned. For size designation, only the longi-

toolmaker's universal vise (fig. 7-8). The flanged

tudinal travel is used. There are six sizes of knee-type

vise provides the most support for a rigid workpiece.

milling machines, with each number representing the

The swivel vise is similar to the flanged vise, but the

number of inches of travel.

setup is less rigid because the workpiece can be

swiveled in a horizontal plane to any required angle.

Standard Size

Longitudinal Table Travel

The toolmaker's universal vise provides the least rigid

support because it is designed to set up the workpiece

No. 1

22 inches

at a complex angle in relation to the axis of the spindle

No. 2

28 inches

and to the surface of the table.

No. 3

34 inches

RIGHT-ANGLE PLATE

No. 4

42 inches

The right-angle plate (fig. 7-9) is attached to the

table. The right-angle slot permits mounting the

No. 5

50 inches

index head so the axis of the head is parallel to the

No. 6

60 inches

milling machine spindle. With this attachment you

can make work setups that are off center or at a right

If the milling machine in your shop is labeled No.

angle to the table T-slots. The standard size plate

2HL, it has a table travel of 28 inches; if it is labeled No.

T-slots make it convenient to change from one setting

5LD, it has a travel of 50 inches. The model designation

to another to mill a surface at a right angle.

is determined by the manufacturer, and features vary

with different brands. The type of milling machine is

TOOLMAKER'S KNEE

designated as plain or universal, horizontal or vertical,

and knee and column or bed. In addition, machines may

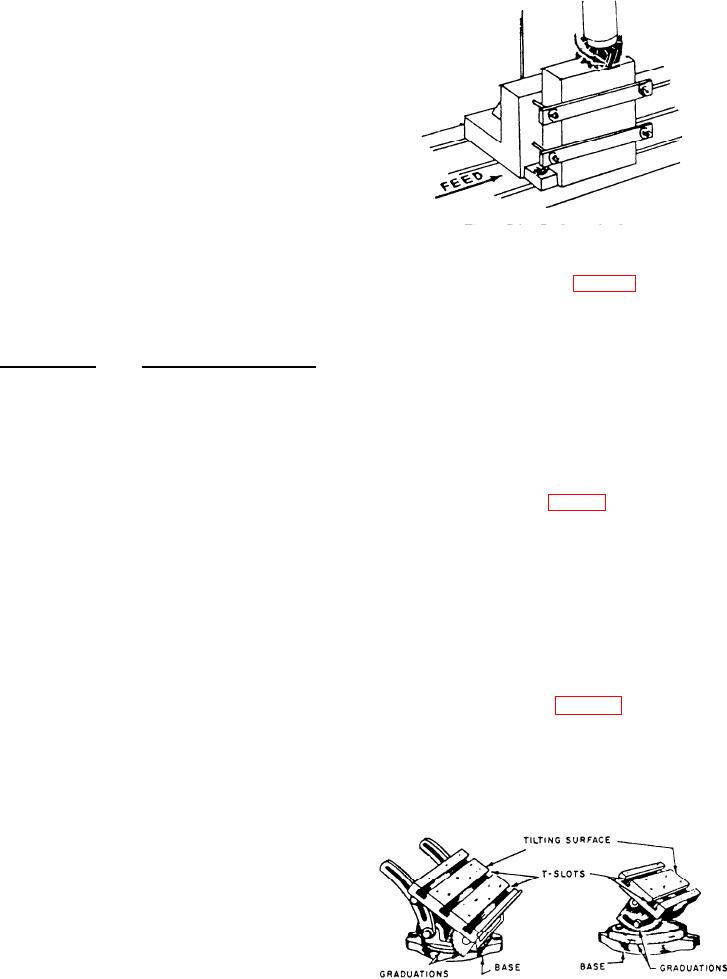

The toolmaker's knee (fig. 7-10) is a simple but

have other special type designations.

useful attachment used to set up angular work, not

Standard equipment used with milling machines

in Navy ships includes workholding devices, spindle

only for milling but also for shaper, drill press, and

attachments, cutters, arbors, and any special tools

grinder operations. You mount a toolmaker's knee,

needed to set up the machines for milling. This

which may have either a stationary or rotatable base,

equipment allows you to hold and cut the great variety

of milling jobs you will find in Navy repair work.

WORKHOLDING DEVICES

The following workholding devices are the ones

you will probably use most frequently.

VISES

The vises commonly used on milling machines

FIgure 7-10.--Toolmaker's knees.

are the flanged plain vise, the swivel vise, and the

7-7