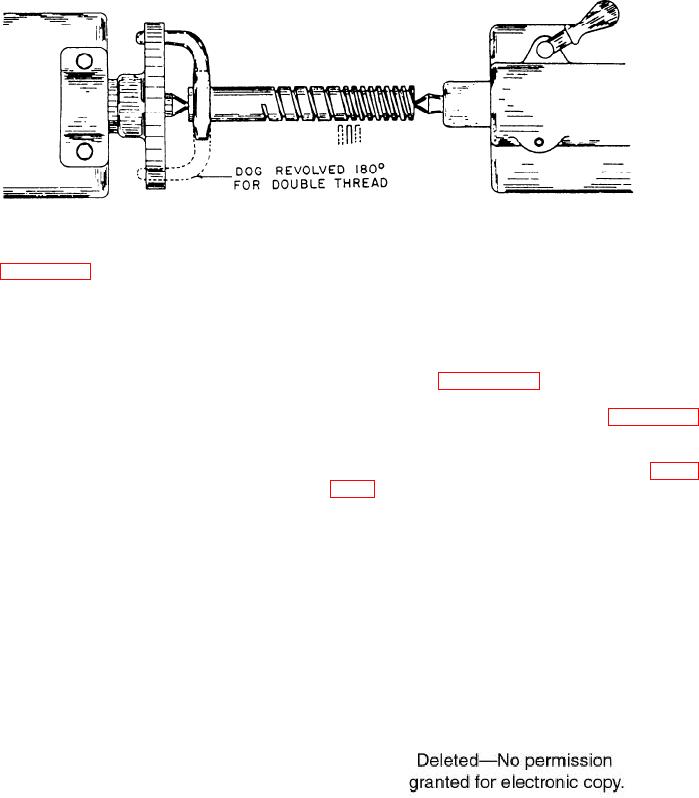

Figure 6-101.--Use of faceplate.

shown in figure 6-101. Two slots are necessary for a

THREADS ON TAPERED WORK

double thread, three slots for a triple thread, and so on.

Use the taper attachment when you cut a thread on

The number of multiples you can cut by this method

tapered work. If your lathe does not have a taper attach-

depends on the number of equally spaced slots there

ment, cut the thread on tapered work by setting over the

are in the drive plate. There are special drive or index

tailstock The setup is the same as for turning tapers.

plates available, so that you can accurately cut a wide

Part A of figure 6-102 shows the method of

range of multiples by this method.

setting the threading tool with the thread gauge when

you use the taper attachment. Part B of figure 6-102

Another method of cutting multiple threads is to

shows the same operation for using the tailstock

setover method.

disengage either the stud gear or the spindle gear from

Note that in both methods illustrated in figure

the gear train in the end of the lathe after you cut a

6-102, you set the threading tool square with the axis

thread groove. Then, turn the work and the spindle

by placing the center gauge on the straight part of the

the required part of a revolution, and reengage the

work, NOT on the tapered section. This is very

gears for cutting the next thread. If you are to cut a

important.

double thread on a lathe that has a 40-tooth gear on

the spindle, cut the first thread groove in the ordinary

manner. Then, mark one of the teeth on the spindle

gear that meshes with the next driven gear. Carry the

mark onto the driven gear, in this case the reversing

gear. Also, mark the tooth diametrically opposite the

marked spindle gear tooth (the 20th tooth of the

40-tooth gear). Count the tooth next to the marked

tooth as tooth number one. Then disengage the gears

by placing the tumbler (reversing) gears in the neutral

position, turn the spindle one-half revolution or 20

teeth on the spindle gear, and reengage the gear train.

You may index the stud gear as well as the spindle

gear. If the ratio between the spindle and stud gears is

not 1 to 1, you will have to give the stud gear a

proportional turn, depending upon the gearing ratio.

The method of indexing the stud or spindle gears is

possible only when you can evenly divide the number

of teeth in the gear indexed by the multiple desired.

Some lathes have a sliding sector gear that you can

readily insert into or remove from the gear train by

shifting a lever. Graduations on the end of the spindle

show when to disengage and to reengage the sector

gear for cutting various multiples.

Figure 6-102.--Cutting thread on tapered work.

6-60