To check the number of threads per inch, place a

rule against the work, as shown in view B of figure

6-93, so that the end of the rule rests on the point of a

thread or on one of the scribed lines. Count the

scribed lines between the end of the rule and the first

inch mark. This will give the number of threads per

inch.

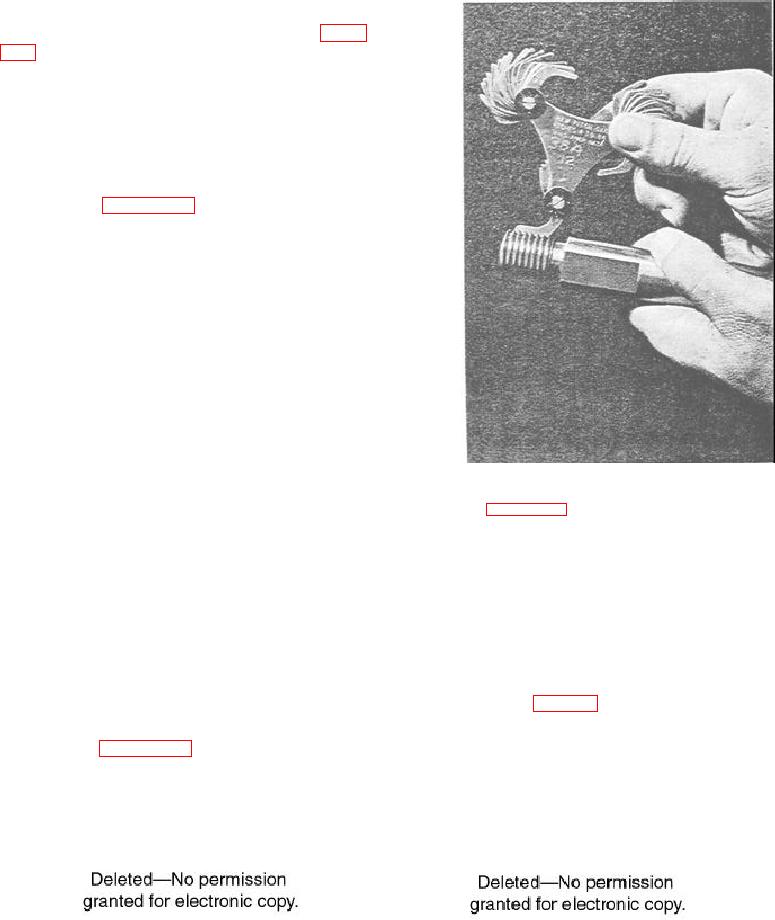

It is quite difficult to accurately count fine pitches

of screw threads. A screw pitch gauge, used as

illustrated in figure 6-94, is very convenient for

checking the finer screw threads. The gauge consists

of a number of sheet metal plates in which are cut the

exact forms of threads of the various pitches; each

plate is stamped with a number indicating the number

of threads per inch for which it is to be used.

If the thread-cutting tool needs resharpening or

gets out of alignment or if you are chasing the threads

on a previously threaded piece, you must reset the tool

so it will follow the original thread groove. To reset

the tool, you may (1) use the compound rest feed

screw and cross-feed screw to jockey the tool to the

proper position, (2) disengage the change gears and

turn the spindle until the tool is positioned properly, or

28.153

(3) loosen the lathe dog (if used) and turn the work

Figure 6-44--Strew pitch gauge.

until the tool is in the proper position in the thread

groove. Regardless of which method you use, you

will usually have to reset the micrometer collars on

To reset the cutting tool into the groove, you will

the cross-feed screw and the compound rest screw.

probably use the compound rest and cross-feed

positioning method. By adjusting the compound rest

Before adjusting the tool in the groove, use the

slide forward or backward, you can move the tool

appropriate thread gauge to set the tool square with

laterally to the axis of the work as well as toward or

the workpiece. Then, with the tool a few thousandths

away from the work. When the point of the tool

of an inch away from the workpiece, start the machine

coincides with the original thread groove (phantom

and engage the threading mechanism. When the tool

view of the tool in fig. 6-95), use the cross-feed screw

has moved to a position near the groove into which

to bring the tool point directly into the groove. When

you plan to put the tool, such as that shown by the

you get a good fit between the cutting tool and the

solid tool in figure 6-95, stop the lathe without

thread groove, set the micrometer collar on the

disengaging the thread mechanism.

cross-feed screw on zero and set the micrometer

Figure 6-95.--Tool must be reset to original groove.

Figure 6-93.--The first cut.

6-57