An example of a pipe thread is shown here.

NPT 1/4-18

where

NPT = tapered pipe thread

1/4 = inside diameter of the pipe in inches

18 = threads per inch

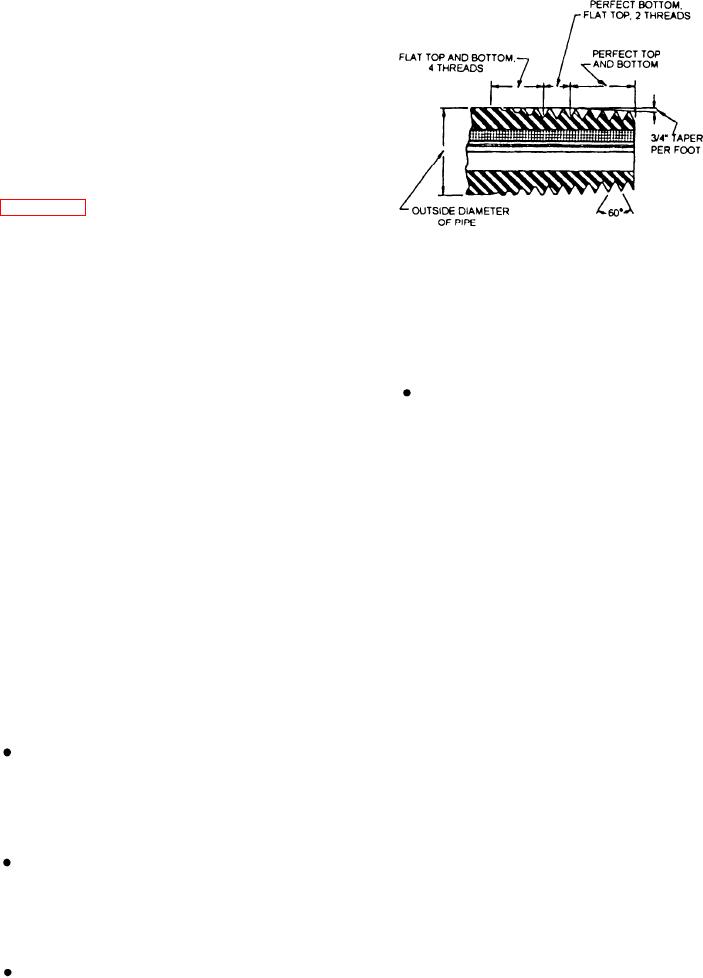

Figure 6-87 shows the typical taper pipe thread.

Straight pipe threads are similar in form to

Figure 6-87.--Typical taper pipe thread.

tapered pipe threads except that they are not tapered.

The same nominal outside diameter and thread

dimensions apply. Straight pipe threads are used for

important. These threads require consistency that is

joining components mechanically and are not

available only through high quality production

s a t i s f a c t o r y for high-pressure applications.

methods combined with a very efficient system of

Sometimes a straight pipe thread is used with a

gauging and inspection.

tapered pipe thread to form a low-pressure seal in a

vibration-free environment.

Class 5: Class 5 threads are interference-fit

threads in which the external threaded member is

CLASSES OF THREADS

larger than the internally threaded member when both

members are in the free state and which, when

Classes of fit for threads are determined by the

assembled, become the same size and develop a

amount of tolerance and allowance allowed for each

holding torque through elastic compression, plastic

particular class. The tolerance (amount that a thread

movement of the material, or both. There are a

may vary from the basic dimension) decreases as the

number of different thread designations within class

class number increases. For example, a class 1 thread

5. They distinguish between external and internal

has more tolerance than a class 3 thread. The pitch

threads and the types of material the external thread

diameter of the thread is the most important thread

will be driven into. This information may be found in

element in controlling the class of fit. The major

the interference-fit threads section of Machinery's

diameter for an external thread and the minor

Handbook.

diameter or bore size for an internal thread are also

important, however, since they control the crest and

MEASURING SCREW THREADS

root clearances more than the actual fit of the thread.

Thread measurement is needed to ensure that the

A brief description of the different classes of fit

thread and its mating part will fit properly. It is

follows:

important that you know the various measuring

Classes 1A and 1B: Class 1A (external) and

methods and the calculations that are used to

class 1B (internal) threads are used where quick and

determine the dimensions of threads.

easy assembly is necessary and where a liberal

The use of a mating part to estimate and check the

allowance is required to permit ready assembly, even

needed thread is common practice when average

with slightly bruised or dirty threads.

accuracy is required. The thread is simply machined

Classes 2A and 2B: Class 2A (external) and

until the thread and the mating part will assemble. A

class 2B (internal) threads are the most commonly

snug fit is usually desired with very little, if any, play

used threads for general applications, including

between the parts.

production of bolts, screws, nuts, and similar threaded

You will sometimes be required to machine

fasteners.

threads that need a specific class of fit, or you may not

have the mating part to use as a gauge. In these cases,

Classes 3A and 3B: Class 3A (external) and

you must measure the thread to make sure you get the

class 3B (internal) threads are used where closeness

required fit.

of fit and accuracy of lead and angle of thread are

6-52