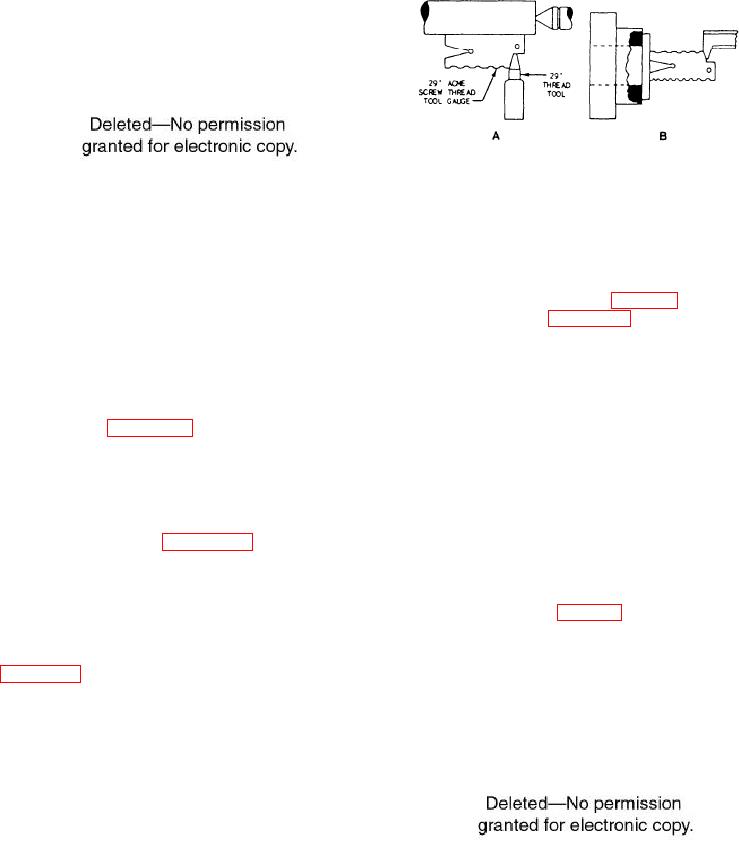

Figure 6-84.--Use of Acme thread tool gauge.

The Acme Screw Thread

The Acme screw thread is used on valve stems,

the lead screw of a lathe, and other places that require

a strong thread. The top and bottom of the threads

Figure 6-83.--Acme thread and formulas for cutting.

have an included angle of 29 (fig. 6-83).

Parts A and B of figure 6-84 show the method of

setting an Acme threading tool for cutting an external

quick-change toolholder you will not need to grind

and internal Acme thread, respectively. Note that a

the top of the tool. If carbide inserts are being used,

29 Acme thread gauge is used in the same manner as

the thread form is already ground.

the center gauge was used for V-form screw threads.

Adjust the cutting edge of the tool to line it up exactly

Grind the point of the tool to an angle of 60, as

with the beveled edge of the gauge. The notches in

shown in A of figure 6-82. Use a center gauge or a

the Acme thread gauge let you grind the squared front

thread tool gauge for grinding the tool to the exact

edge of the tool bit accurately according to the pitch

angle required. The top of the tool is usually ground

of the thread to be machined.

flat, with no side rake or back rake. However, for

In cutting an Acme thread, be sure the clearance is

cutting threads in steel, side rake is sometimes used.

0.010 inch between the top of the thread of the screw

Set the threading tool square with the work, as

and the bottom of the thread of the nut in which it fits.

shown in B and C of figure 6-82. Use the center

gauge to adjust the point of the threading tool; if you

The Square Thread

carefully set the tool, a perfect thread will result. If

you do not set the threading tool perfectly square with

The square thread (fig. 6-85) is used when heavy

the work, the angle of the thread will be incorrect.

threads are required, such as in jack screws, press

For cutting external threads, place the top of the

screws, and feed screws. It is used for much the same

threading tool exactly on center as shown in D of

figure 6-82. Note that the top of the tool is ground flat

and is in exact alignment with the lathe center. This is

necessary to obtain the correct angle of the thread.

The size of the threading tool for cutting an

internal thread is important. The tool head must be

small enough to be backed out of the thread and still

leave enough clearance to be drawn from the threaded

hole without injuring the thread. However, the boring

bar that holds the threading tool for internal threading

should be both as large as possible in diameter and as

short as possible to keep it from springing away from

the work during cutting.

OTHER FORMS OF THREADS

In the following section, other forms of screw

threads are illustrated with pertinent information on

cutting these threads.

Figure 6-85.--Square thread and formulas.

6-50