purpose as the Acme thread, which is used in many

places where the square thread was formerly used.

The disadvantage of square threads is that the straight

sides do not allow sideplay adjustment.

The cutting edge width of the tool for cutting

square screw threads is exactly one-half the pitch, but

the width of the edge of the tool for threading nuts is

from 0.001 to 0.003 inch larger. This permits a

sliding fit on the screw.

Set the threading tool for cutting square threads

square with the work.

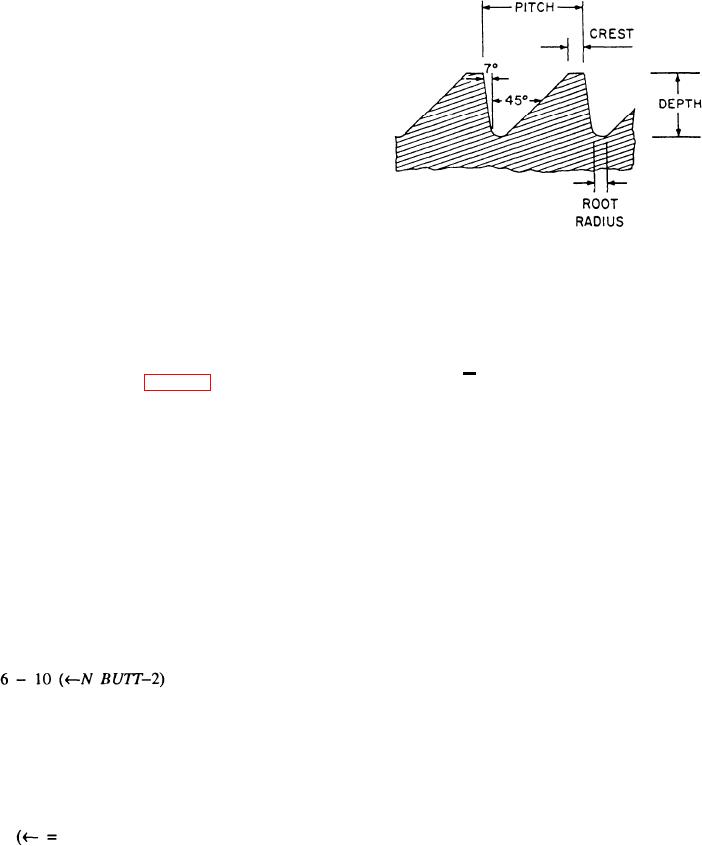

Figure 6-86.--Buttress thread.

Be sure the clearance between the top of the

screw thread and the bottom of the nut thread is about

0.005 to 0.008 inch for each inch of thread diameter.

The formulas for the basic dimensions of the

American Standard buttress external thread are as

Buttress Thread

follows:

1

Pitch = n

On a buttress thread (fig. 6-86) the load resisting

side is nearly perpendicular to the thread axis and is

Width of flat at crest = 0.1631 pitch

called the pressure flank. The American Standard

form of the buttress thread has a 7 angle on the

Root radius = 0.0714 pitch

pressure flank; other forms have 0, 3, or 5.

Depth of thread = 0.6627 pitch

However, the American Standard form is most often

used, and the formulas in this section apply to this

The classes of fit are 1 = free, 2 = medium,

form. The buttress thread can be designed to either

3 = close. The specific dimensions involved concern

push or pull against the internal thread of the mating

the tolerance of the pitch diameter and the major

part into which it is screwed. The direction of the

diameter and vary according to the nominal or basic

thrust will determine the way you grind your tool for

size. Consult a handbook for specific information on

machining the thread. An example of the designation

the dimensions for the various classes of fit.

symbols for an American Standard buttress thread

form is as follows:

Pipe Threads

American National Standard pipe threads are

similar to the unified threads in that both have an

where

included angle of 60 and a flat on the crest and the

root of the thread. Pipe threads can be either tapered

6 = basic major diameter of 6.000 inches

or straight, depending on the intended use of the

threaded part. A description of the two types is given

10 = 10 threads per inch

in the following paragraphs.

Tapered pipe threads are used to provide a

internal member to push against

pressure-tight joint when the internal and external

external member)

mating parts are assembled correctly. Depending on the

closeness of the fit of the mating parts, you may need to

N BUTT = National Buttress Form

use a sealing tape or a sealer (pipe compound) to prevent

leakage at the joint. The taper of the threads is 3/4 inch

2 = class of fit

per foot. Machine and thread the section of pipe at this

NOTE: A symbol such as "←(" indicates that the

angle. The hole for the internal threads should be

slightly larger than the minor diameter of the small end

internal member is to pull against the external

of the externally threaded part.

member.

6-51