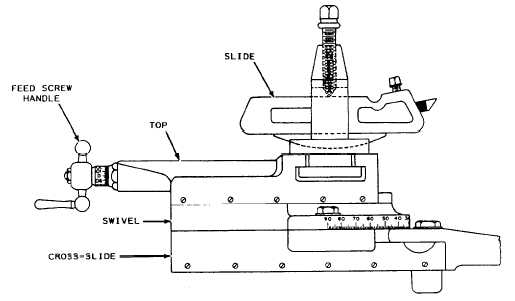

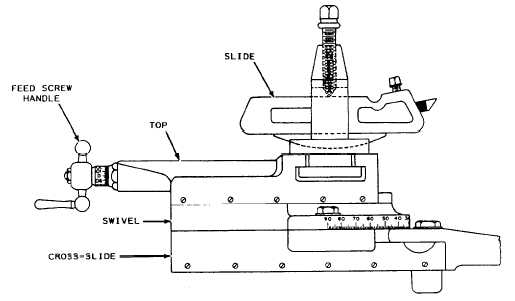

Figure 9-4.—Compound rest.

The rotating feed rod drives gears in the apron; these

gears in turn drive the longitudinal feed and crossfeed

mechanisms through friction clutches.

Some lathes do not have a separate feed rod, but use

a spline in the lead screw for the same purpose.

Lead Screw

The lead screw is used for thread cutting. It has

accurately cut Acme threads along its length that engage

the threads of half-nuts in the apron when the half-nuts

are clamped over it. The lead screw is driven by the

spindle through a gear train. Therefore, the rotation of

the lead screw bears a direct relation to the rotation of

the spindle. When the half-nuts are engaged, the

longitudinal movement of the carriage is controlled

directly by the spindle rotation. Consequently, the

cutting tool is moved a definite distance along the work

for each revolution that the spindle makes.

Crossfeed Slide

The crossfeed slide is mounted to the top of the

carriage in a dovetail and moves on the carriage at a right

angle to the axis of the lathe. A crossfeed screw allows

the slide to be moved toward or away from the work in

accurate increments.

Compound Rest

The compound rest (fig. 9-4), mounted on the

compound slide, provides a rigid adjustable mounting

for the cutting tool. The compound rest assembly has the

following principal parts:

1. The compound rest SWIVEL, which can be

swung around to any desired angle and clamped in

position. It is graduated over an arc of 90° on each side

of its center position for easier setting to the angle

selected. This feature is used for machining short, steep

tapers, such as the angle on bevel gears, valve disks, and

lathe centers.

2. The compound rest, or TOP SLIDE, which is

mounted on the swivel section on a dovetailed slide. It

is moved by the compound rest feed screw.

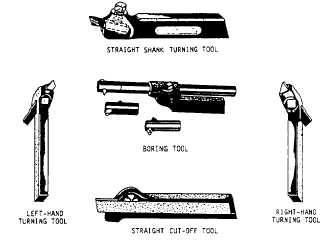

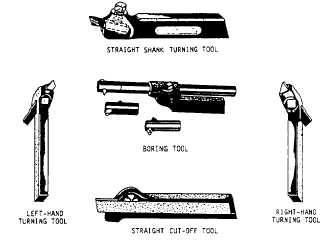

Figure 9-5.—Common types of toolholders.

9-4