CHAPTER 9

LATHES AND LATHE MACHINING OPERATIONS

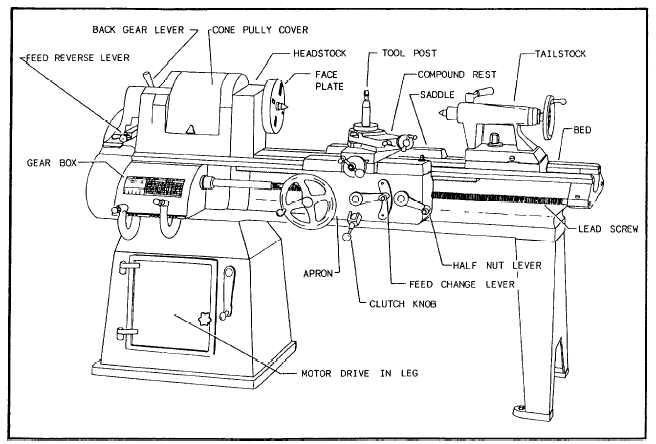

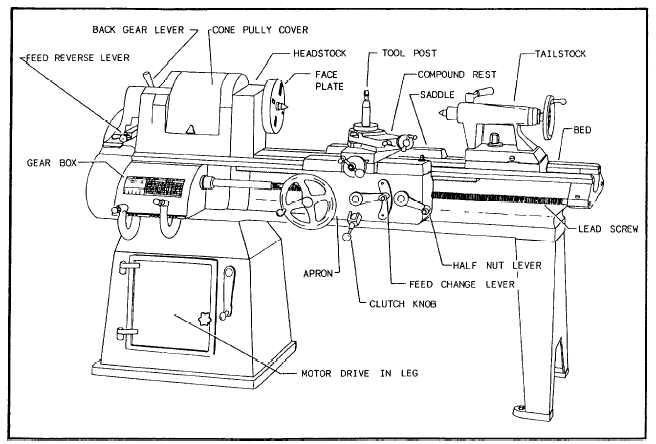

The engine lathe, its use, and its principal parts and

their uses are knowledges and skills expected of an EN2.

Although machine shop work is generally done by

personnel in the Machinery Repairman (MR) rating,

there may be times that you will find the lathe essential

to complete a repair job. This chapter will help you to

identify the engine lathe’s attachments, accessories, and

their uses. Also, it will identify and explain different

machining operations and the factors related to

machining operations. Of course, you will be expected

to know and to follow the safety precautions associated

with machining operations.

There are a number of different types of lathes

installed in the machine shops in various Navy ships.

These include the engine lathe, the horizontal turret

lathe, and several variations of the basic engine lathe,

such as bench, toolroom, and gap lathes. All lathes,

except the vertical turret type, have one thing in

common. For all usual machining operations, the

workpiece is held and rotated about a horizontal axis,

while being formed to size and shape by a cutting tool.

In the vertical turret lathe, the workpiece is rotated about

a vertical axis. Of the various types of lathes, the type

you are most likely to use is the engine lathe. Therefore,

this chapter deals only with engine lathes and the

machining operations you may have to perform.

NOTE: Before you attempt to operate any lathe,

make sure you know how to operate it. Read all operating

instructions supplied with the machine. Learn the locations

of the various controls and how to operate them.

ENGINE LATHE

An engine lathe similar to the one shown in figure

9-1 is found in every machine shop. It is used mostly for

Figure 9-1.—Typical engine lathe.

9-1