turning, boring, facing, and thread cutting. But it may

also be used for drilling, reaming, knurling, grinding,

spinning, and spring winding. Since you will primarily

be concerned with turning, boring, facing, and thread

cutting, we will deal primarily with those operations in

this chapter.

The work held in the engine lathe can be revolved

at any one of a number of different speeds, and the

cutting tool can be accurately controlled by hand or

power for longitudinal feed and crossfeed.

(Longitudinal feed is the movement of the cutting tool

parallel to the axis of the lathe; crossfeed is the

movement of the cutting tool perpendicular to the axis

of the lathe.)

Lathe size is determined by two measurements: (1)

the diameter of work it will swing (turn) over the ways

and (2) the length of the bed. For example, a 14-inch by

6-foot lathe will swing work up to 14 inches in diameter

and has a bed that is 6 feet long.

Engine lathes vary in size from small bench lathes

that have a swing of 9 inches to very large lathes for

turning large diameter work such as low-pressure

turbine rotors. The 16-inch lathe is the average size for

general purposes and is the size usually installed in ships

that have only one lathe.

PRINCIPAL PARTS

To learn the operation of the lathe, you must be

familiar with the names and functions of the principal

parts. Lathes from different manufacturers differ

somewhat in construction, but all are built to perform

the same general functions. As you read the description

of each part, find its location on the lathe in figure 9-1

and the figures that follow. (For specific details of

features of construction and operating techniques, refer

to the manufacturer’s technical manual for your

machine.)

Bed and Ways

The bed is the base or foundation of the parts of the

lathe. The main feature of the bed is the ways, which are

formed on the bed’s upper surface and run the full length

of the bed. The ways keep the tailstock and the carriage,

which slide on them, in alignment with the headstock.

Headstock

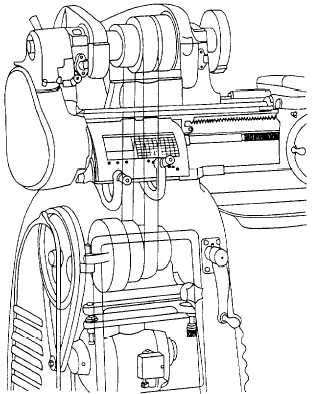

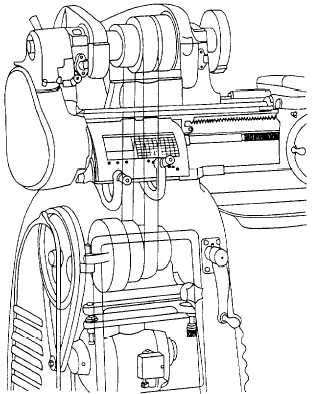

The headstock contains the headstock spindle and

the mechanism for driving it. In the belt-driven type,

shown in figure 9-2, the driving mechanism consists of

Figure 9-2.—Belt-driven type of headstock.

a motor-driven cone pulley that drives the spindle cone

pulley through a drive belt. The spindle can be rotated

either directly or through back gears.

When the headstock is set up for direct drive, a

bull-gear pin, located under a cover to the right of the

spindle pulley, connects the pulley to the spindle. This

connection causes the spindle to turn at the same speed

as the spindle pulley.

When the headstock is set up for gear drive, the

bull-gear pin is pulled out, disconnecting the spindle

pulley from the spindle. This allows the spindle to turn

freely inside the spindle pulley. The back-gear lever, on

the left end of the headstock, is moved to engage the

back-gear set with a gear on the end of the spindle and

a gear on the end of the spindle pulley. In this drive

mode, the drive belt turns the spindle pulley, which turns

the back-gear set, which turns the spindle.

Each drive mode provides four spindle speeds, for

a total of eight. The back-gear drive speeds are less

slower than the direct-drive speeds.

Tailstock

The primary purpose of the tailstock is to hold the

dead center to support one end of the work being

9-2