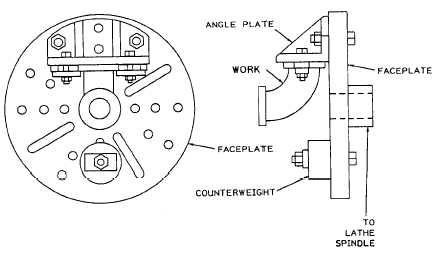

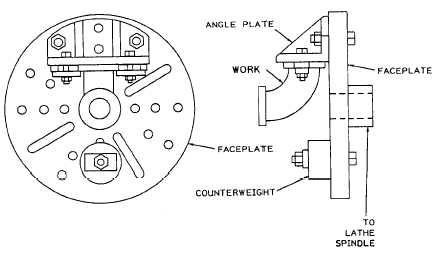

Figure 9-10.—Faceplate.

tool so that the cutting edge is on the right side of the

cutter bit and may be fed in toward the headstock.

Inside-Threading Tool.—The

inside-threading

tool (fig. 9-7, view J) has the same shape as the

threading tool in figure 9-7, view E, but it is usually

much smaller. Boring and inside-threading tools may

require larger relief angles when used in small

diameter holes.

LATHE CHUCKS.—The lathe chuck is a device

for holding lathe work. It is mounted on the nose of

the spindle. The work is held by jaws which can be

moved in radial slots toward the center of the chuck

to clamp down on the sides of the work. These jaws

are moved in and out by screws turned by a special

chuck wrench.

The four-jaw independent lathe chuck, view A in

figure 9-8, is the most practical chuck for general work

The four jaws are adjusted one at a time, making it

possible to hold work of various shapes and to adjust the

center of the work to coincide with the axis of the

spindle. The jaws are reversible.

The three-jaw universal or scroll chuck, view B in

figure 9-8, can be used only for holding round or

hexagonal work All three jaws move in and out together

in one operation and bring the work on center

automatically. This chuck is easier to operate than the

four-jaw type, but, when its parts become worn, its

accuracy in centering cannot be relied upon. Proper

lubrication and constant care are necessary to ensure

reliability.

The draw-in collet chuck is used to hold small

work for machining in the lathe. It is the most

accurate type of chuck made and is intended for

precision work. Figure 9-9 shows the parts

assembled in place in the lathe spindle. The collet,

which holds the work, is a split-cylinder with an

outside taper that fits into the tapered closing

sleeve and screws into the threaded end of the

hollow drawbar. As the handwheel is turned

clockwise, the drawbar is moved toward the

handwheel. This tightening up on the drawbar pulls

the collet back into the tapered sleeve, thereby

closing it firmly over the work and centering the

work accurately and quickly. The size of the hole

in the collet determines the diameter of the work

the chuck can handle.

Faceplates

The faceplate is used for holding work that,

because of its shape and dimensions, cannot be swung

between centers or in a chuck. The T-slots and other

openings on its surface provide convenient anchors

for bolts and clamps used in securing the work to it.

The faceplate is mounted on the nose of the spindle.

(See fig. 9-10.)

The driving plate is similar to a small faceplate

and is used mainly for driving work that is held

between centers. The primary difference between a

faceplate and a driving plate is that a faceplate has a

machined face for precision mounting, while the face

of a driving plate is left rough. When a driving plate

is used, the bent tail of a dog clamped to the work is

inserted into a slot in the faceplate. This transmits

rotary motion to the work.

9-7