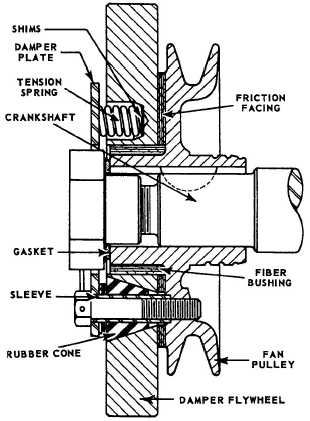

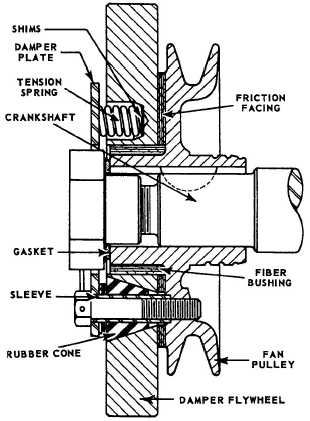

Figure 12-21.-Sectional view of a typical

vibration damper.

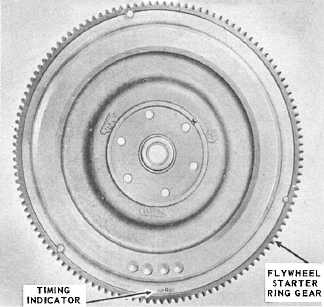

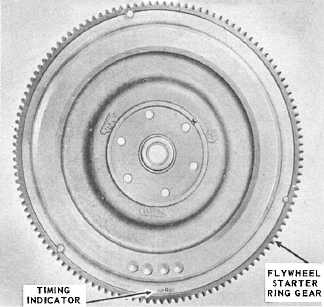

Engine Flywheel

The flywheel mounts at the rear of the crankshaft

near the rear main bearing. This is usually the longest

and heaviest main bearing in the engine, as it must

support the weight of the flywheel.

The flywheel (fig. 12-22) stores up rotation energy

during the power impulses of the engine. It releases

this energy between power impulses, thus assuring

less fluctuation in engine speed and smoother engine

operation. The size of the flywheel will vary with the

number of cylinders and the general construction of

the engine. With the large number of cylinders and the

consequent overlapping of power impulses, there is less

need for a flywheel; consequently, the flywheel can be

relatively small. The flywheel rim carries a ring gear,

either integral with or shrunk on the flywheel, that

meshes with the starter driving gear for cranking the

engine. The rear face of the flywheel is usually

machined and ground and acts as one of the pressure

surfaces for the clutch, becoming a part of the clutch

assembly.

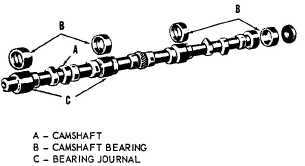

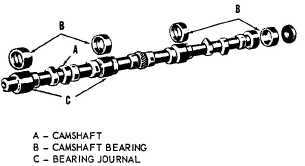

Figure 12-23.-Camshaft and bushings.

Valves and Valve Mechanisms

Most engines have two valves for each cylinder, one

intake and one exhaust valve. Since each of these

valves operates at different times, separate operating

mechanisms must be provided for each valve. Valves

are normally held closed by heavy springs and by

compression in the combustion chamber. The purpose

of the valve-actuating mechanism is to overcome the

spring pressure and open the valves at the proper time.

The valve-actuating mechanism includes the engine

camshaft, camshaft followers (tappets), pushrods, and

rocker arms.

CAMSHAFT.—The camshaft (fig. 12-23) is enclosed in

the engine block. It has eccentric lobes (cams) ground

on it for each valve in the engine. As the

12-19