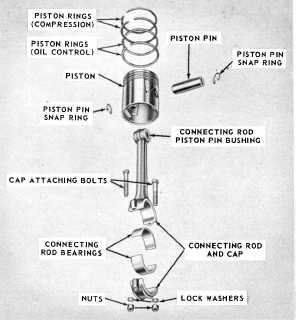

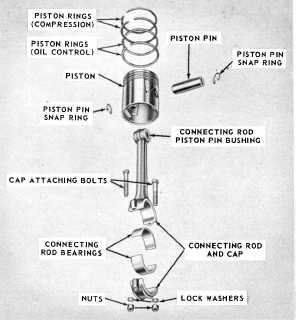

Figure 12-13.—Piston and connecting rod (exploded

view).

a carrier for the piston rings used to seal the

compression in the cylinder. (See. fig. 12-13.)

The piston must come to a complete stop at the

end of each stroke before reversing its course in the

cylinder. To withstand this rugged treatment and

wear, it must be made of tough material, yet be light

in weight. To overcome inertia and momentum at

high speed, it must be carefully balanced and

weighed. All the pistons used in any one engine must

be of similar weight to avoid excessive vibration. Ribs

are used on the underside of the piston to reinforce

the hand. The ribs also help to conduct heat from the

head of the piston to the piston rings and out through

the cylinder walls.

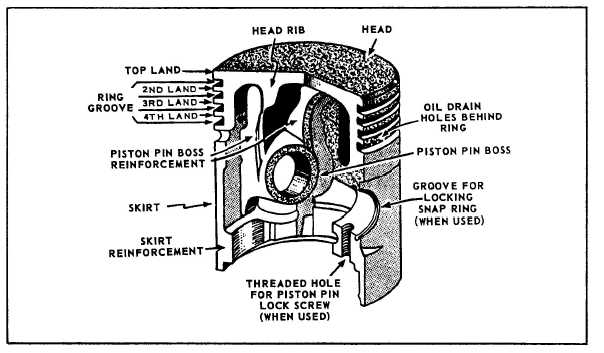

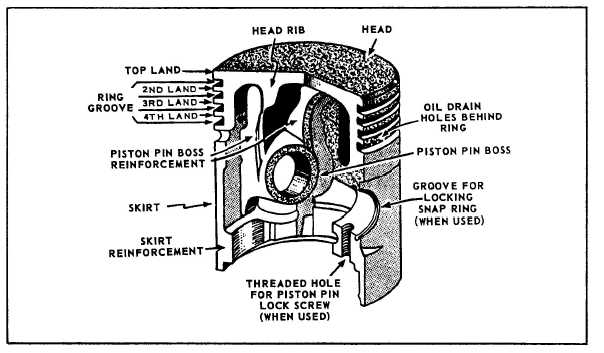

The structural components of the piston are the

head, skirt, ring grooves, and land (fig. 12-14).

However, all pistons do not look like the typical one

illustrated here. Some have differently shaped heads.

Diesel engine pistons usually have more ring grooves

and rings than gasoline engine pistons. Some of these

rings may be installed below as well as above the

wrist or piston pin (fig. 12-15).

Fitting pistons properly is important. Because

metal expands when heated and space must be

provided for lubricants between the pistons and the

cylinder walls, the pistons are fitted to the engine

with a specified clearance. This clearance depends

upon the size or diameter of the piston and the

material form which it is made. Cast iron does not

expand as fast or as much as aluminum. Aluminum

pistons require more clearance to prevent binding or

seizing when the engine gets hot. The skirt of bottom

part of the piston runs much cooler than the top;

therefore, it does not require as much clearance as

the head.

Figure 12-14.—The parts of a piston.

12-14