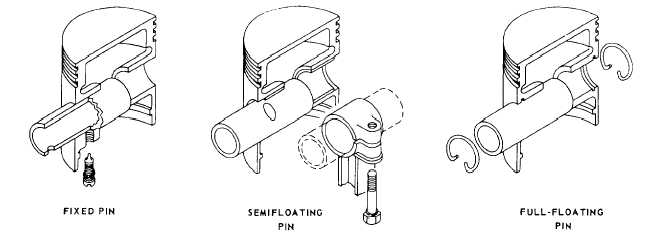

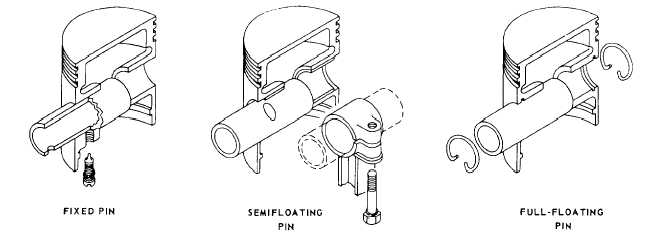

Figure 12-17.-Piston pin types.

expanded by the heat generated during operation, it

becomes round because the expansion is proportional to

the temperature of the metal. The walls of the skirt are

cut away as much as possible to reduce weight and to

prevent excessive expansion during engine operation.

Many aluminum pistons are made with split skirts so

that when the pistons expand, the skirt diameter will not

increase.

The two types of piston skirts found in most engines

are the full trunk and the slipper. The full-trunk-type

skirt, more widely used, has a full cylindrical shape with

bearing surfaces parallel to those of the cylinder, giving

more strength and better control of the oil film. The

slipper-type (cutaway) skirt has considerable relief on

the sides of the skirt, leaving less area for possible

contact with the cylinder walls and thereby reducing

friction.

PISTON PINS.— The piston is attached to the

connecting rod by the piston pin (wrist pin). The pin

passes through the piston pin bosses and through the

upper end of the connecting rod, which rides within the

piston on the middle of the pin. Piston pins are made of

alloy steel with a precision finish and are case hardened

and sometimes chromium plated to increase their

wearing qualities. Their tubular construction gives them

maximum strength with minimum weight. They are

lubricated by splash from the crankcase or by pressure

through passages bored in the connecting rods.

Three methods are commonly used for fastening a

piston pin to the piston and the connecting rod: fixed

pin, semifloating pin, and full-floating pin (fig. 12-17).

The anchored, or fixed, pin attaches to the piston by a

screw running through one of the bosses; the connecting

rod oscillates on the pin. The semifloating pin is

anchored to the connecting rod and turns in the piston

pin bosses. The full-floating pin is free to rotate in the

connecting rod and in the bosses, while plugs or

snap-ring locks prevent it from working out against the

sides of the cylinder.

PISTON RINGS.— Piston rings are used on

pistons to maintain gastight seals between the pistons

and cylinders, to aid in cooling the piston, and to control

cylinder-wall lubrication. About one-third of the heat

absorbed by the piston passes through the rings to the

cylinder wall. Piston rings are often complicated in

design, are heat treated in various ways, and are plated

with other metals. Piston rings are of two distinct

classifications: compression rings and oil control rings.

(See fig. 12-18.)

The principal function of a compression ring is to

prevent gases from leaking by the piston during the

compression and power strokes. All piston rings are split

to permit assembly to the piston and to allow for

expansion. When the ring is in place, the ends of the split

joint do not form a perfect seal; therefore, more than one

ring must be used, and the joints must be staggered

around the piston. If cylinders are worn, expanders (figs.

12-15 and 12-18) are sometimes used to ensure a perfect

seal.

The bottom ring, usually located just above the

piston pin, is an oil-regulating ring. This ring scrapes the

excess oil from the cylinder walls and returns some of

it, through slots, to the piston ring grooves. The ring

groove under an oil ring has openings through which the

oil flows back into the crankcase. In some engines,

additional oil rings are used in the piston skirt below the

piston pin.

12-16