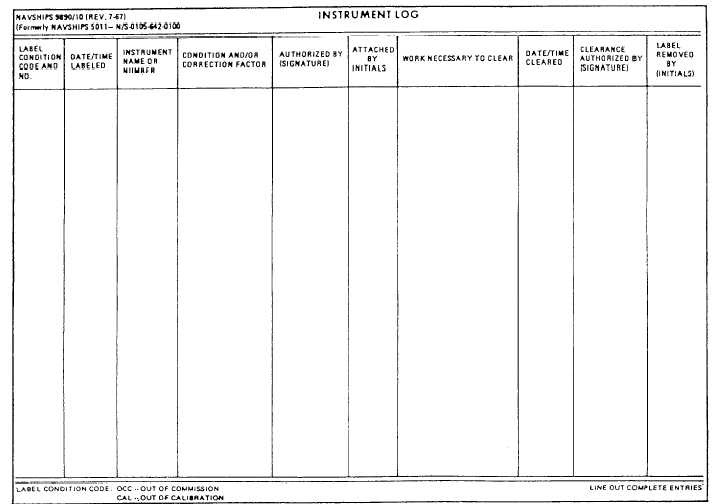

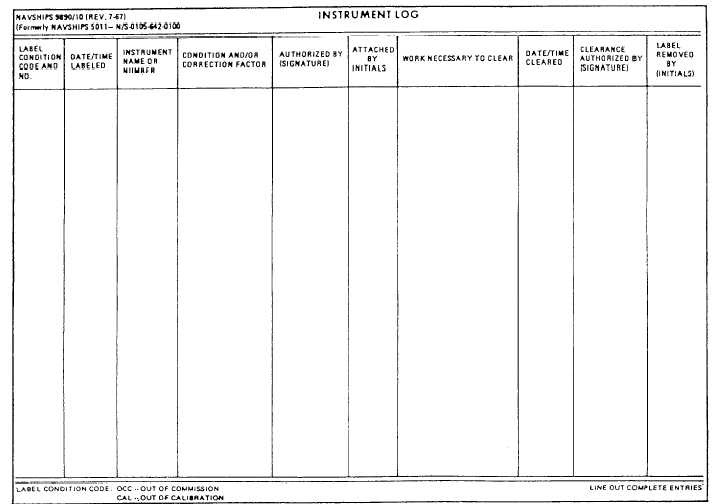

Figure 1-13.—Instrument Log.

transferred to this section of the log until they are

reviewed and removed by the department head.

TAG-OUT INFORMATION

A tag-out procedure is necessary because of the

complexity of modem ships and the cost, delays, and

hazards to personnel that can result from the improper

operation of equipment. Learn and use the following

guidelines:

1. Enforce the tag-out procedure at all times. You

must do this during normal operations as well as during

construction, testing, repair, or maintenance.

2. Do not use tags or labels as a substitute for other

safety measures. Examples are chaining or locking

valves, removing fuses, or racking out circuit breakers.

However, you must attach tags to the fuse panel, the

racked-out circuit breaker cabinet, or a locked valve to

show a need for action. You do not need to use tags

where a device will be locked during normal operations.

3. Use tags to show the presence of, and the

requirement for, freeze seals, blank flanges, or similar

safety devices. When equipment or components are

placed out of commission, use the tag-out procedures to

control the status of the affected equipment. Examples

are disconnecting electrical leads, providing jumpers, or

pulling fuses for testing or maintenance.

4. Never use tag-outs to identify valves, to mark

leaks, or for any purpose not specified in the tag-out

procedure.

5. Do not laminate tags or labels for reuse. The

reuse of tags or labels is not allowed.

1-14