intake air, piston seizure, and defective auxiliary drive

mechanisms.

Misfiring

When an engine misfires or fires erratically or when

one cylinder misfires regularly, the possible troubles are

usually associated with the fuel or fuel system, worn

parts, or the air cleaner or silencer. In determining what

causes a cylinder to misfire, you should follow

prescribed procedures in the appropriate technical

manual. Procedures will vary among engines because of

differences in the design of parts and equipment.

Many of the troubles caused by fuel contamination

require overhaul and repair. However, a cylinder may

misfire regularly in some systems because of the fuel

pump cutout mechanism. Some fuel pumps have this

type of mechanism so the fuel supply can be cut off from

a cylinder to measure compression pressures. When a

cylinder is misfiring, check first for an engaged cutout

mechanism (if installed), and disengage it during normal

engine operation.

LOSS OF COMPRESSION.–A cylinder may

misfire due to loss of compression, which may be caused

by a leaking cylinder head gasket, leaking or sticking

cylinder valves, worn pistons, liners or rings, or a

cracked cylinder head or block If loss of compression

pressure causes an engine to misfire, check the

compression pressure of each cylinder. Some indicators

measure compression as well as firing pressure while

the engine is running at full speed. Others check only

the compression pressures with the engine running at a

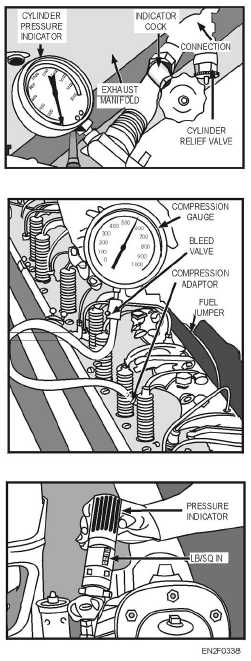

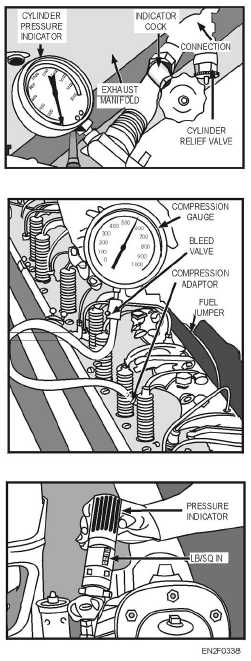

relatively slow speed. Figure 3-38 illustrates the

application of some different types of pressure

indicators.

After you install an indicator, operate the engine at

the specified rpm and record the cylinder compression

pressure. Follow this procedure on each cylinder in turn.

The pressure in any one cylinder should not be lower

than the specified psi, nor should the pressure for any

one cylinder be excessively lower than the pressures in

the other cylinders. The maximum pressure variation

permitted between cylinders is given on engine data

sheets or in the manufacturer’s technical manual. A

compression leak is indicated when the pressure in one

cylinder is considerably lower than that in the other

cylinders.

If a test indicates a compression leak, you will have

to do some disassembly, inspection, and repair. Check

the valve seats and cylinder head gaskets for leaks, and

inspect the valve stems for sticking. A cylinder head or

block may be cracked. If these parts are not the source

of trouble, compression is probably leaking past the

piston because of insufficient sealing of the piston rings.

Improper Cooling Water Temperature

If an engine is to operate properly, the cooling water

temperature must be maintained within specified

temperature limits. When cooling water temperature

drops lower than recommended for a diesel engine,

Figure 3-38.–Engine cylinder pressure indicator application.

3-31