1. Always stop the work before you take a

measurement. DO NOT measure moving parts because

the micrometer may get caught in the rotating work and

be severely damaged.

2. Always open a micrometer by holding the frame

with one hand and turning the knurled sleeve with the

other hand. Never open a micrometer by twirling the

frame, because such practice will put unnecessary strain

on the instrument and cause excessive wear of the

threads.

3. Apply only moderate force to the knurled

thimble when you take a measurement. Always use the

friction slip ratchet if there is one on the instrument. Too

much pressure on the knurled sleeve will not only result

in an inaccurate reading, but also will cause the frame

to spring and force the measuring surface out of line.

4. When a micrometer is not in use, place it where

it will not drop. Dropping a micrometer will cause the

micrometer frame to spring. If you drop a micrometer,

check it for accuracy before you take further readings.

5. Before you store a micrometer, back the spindle

away from the anvil, wipe all exterior surfaces with a

clean, soft cloth, and coat the surfaces with a light oil.

Do not reset the measuring surfaces to close contact

because the protecting film of oil on these surfaces will

be squeezed out.

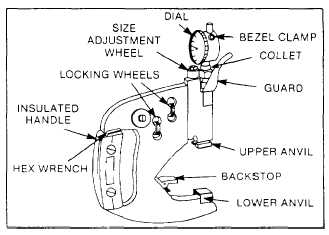

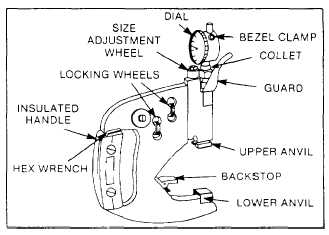

SNAP GAUGE

The snap gauge compares the outside diameters of

parts such as shafts and journals to a standard. It can

compare diameters from zero to 8 inches at an accuracy

of 0.0001 inch. Figure 2-5 shows a typical snap gauge.

Most snap gauges consist of a frame with an

insulated handle, a hex wrench mounted in the handle,

dial indicator digits calibrated in 0.00l-inch divisions, a

bezel clamp, adjustment wheels, locking wheels, a

backstop, a lower anvil, an upper anvil, and a guard.

Whenever you use a snap gauge, use the handle and

avoid touching the gauge proper because body heat may

affect the reading. For the same reason, handle the

standard plugs only by their plastic end. Clean the anvils

and the backstop with a clean cloth. To use the snap

gauge, follow the manufacturer’s operating instructions.

After you record the readings and compare the

readings with the design specifications, clean and store

the snap gauge in its appropriate storage location.

Figure 2-5.—Typical snap gauge.

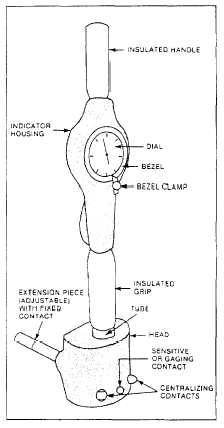

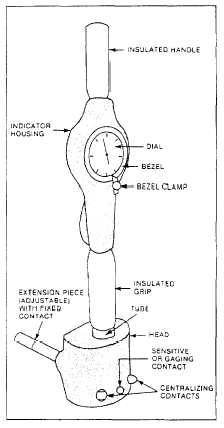

BORE GAUGES

The dial bore gauge is one of the most accurate tools

for measuring a cylindrical bore or for checking a bore

for out-of-roundness or taper. The gauge does not give

a direct measurement. It identifies the amount of

deviation from a preset size or the amount of deviation

from one part of the bore to another. A master ring gauge,

outside micrometer, or vernier caliper can be used to

preset the gauge. Figure 2-6 shows a typical bore gauge.

Figure 2-6.—Typical bore gauge.

2-4