Most bore gauges consist of a dial indicator,

extension pieces, bezel and locknut, spring-loaded

guide, and sensor button.

Before you start a measuring procedure, expose

both the bore gauge and the master ring gauge, or any

other tools used to preset the bore gauge, and the part to

be measured to the same work place environment for

one hour. If you fail to do this, a temperature differential

may cause your readings to be inaccurate. When you use

the bore gauge, touch only its insulated handle.

The gauge has two stationary spring-loaded points

and an adjustable point to permit a variation in range.

These points are evenly spaced to allow accurate

centering of the tool in the bore. A fourth point, the tip

of the dial indicator, is located between the two

stationary points. By simply rocking the tool in the bore,

you can observe the amount of variation on the dial.

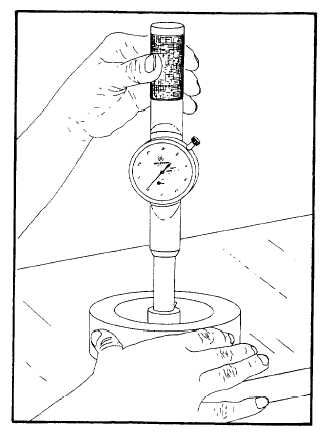

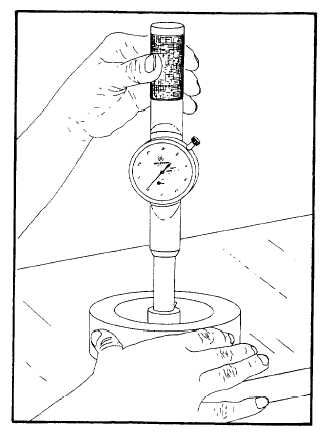

Figure 2-7 shows a bore gauge inside a bore being

moved in a gentle rocking motion. Always follow the

bore gauge manufacturer’s operating manual. Measure

the bore and mark the areas you measure. A good

Figure 2-7.—Measuring a bore with a bore gauge.

practice is to check the bore gauge in the standard after

you take each set of measurements to ensure that

readings are accurate.

STRAIN/DEFLECTION GAUGE

A strain or deflection gauge is used to check the

crankshaft alignment on large diesel engines. It is a

specially adapted dial indicator that fits between the

crank webs. The strain gauge reads the flexing motion

of the webs directly as the crankshaft is slowly rotated

(correct engine rotation). The gauge dial reads in

0.00l-inch graduations.

The strain gauge consists of a dial indicator, contact

point, balancing attachment, clamping nut, spring

plunger, rods and extension, and bezel.

Before you take a reading, be sure the engine is

completely assembled and cold. Place the strain gauge

between the webs of a crankthrow, as far as possible

from the axis of the crankpin. The ends of the indicator

should rest in the prick-punch marks in the crank webs.

If these marks are not present, consult the

manufacturer’s technical manual for the proper location

of the marks. Ensure that the strain gauge is at the same

temperature as the engine. A temperature differential

may cause inaccurate readings. Readings are generally

taken at the four crank positions; top dead center,

inboard, near or at bottom dead center, and outboard

However, the manufacturer’s technical manual for the

specific engine provides information concerning the

proper positions of the crank for taking readings. In

some situations, due to the position of the dial, you may

need to use a mirror and a flashlight to read the gauge.

Once you have placed the indicator in position for the

first reading, DO NOT touch the gauge until you have

taken and recorded all four readings. Variations in the

readings taken at the four crank positions indicate

distortion of the crank, which may be caused by any of

several factors, such as a bent crankshaft, worn bearings,

or improper engine alignment. The manufacturer’s

technical manual will provide you with the maximum

allowable deflection. Figure 2-8 shows the locations for

taking crankshaft deflection readings.

BORESCOPE

A borescope is used to inspect internal parts on an

engine without having to disassemble the engine. This

instrument helps a great deal in estimating the amount

of repair work needed and the time required for the

repair. Figure 2-9 shows a typical borescope.

2-5