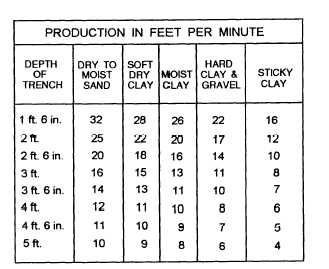

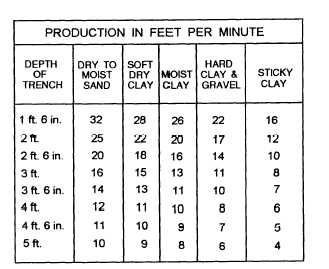

Table 9-1.—Crawler Ditcher Maximum Trenching Rates

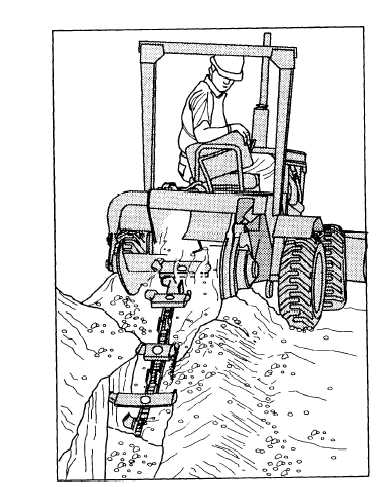

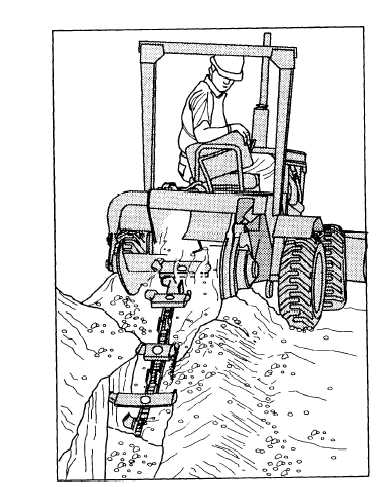

Figure 9-69.—Chain ditcher.

The guideline should be established at a height that

will put it at least a few inches above the ground at all

points, stakes driven along it, and the exact height or

depth of the cut marked. Then a string line is stretched

along the stakes on these markings.

A rigid bar is fastened to the front of the power unit

of the ditcher with one end over the string when the

ditcher is centered on the ditch line. A plumb bob or

other weight is fastened to the bar, so it hangs directly

over the string. The operator can then keep the machine

on center of the trench, cut by keeping the plumb

bob just over the string. If the ground is irregular and

causes the ditcher to go up and down, the cord holding

the plumb bob can be run through eyes or pulleys, so

the operator can reach an end of the cord to raise and

lower it.

The same device (plumb bob or other weight) can

be fastened on the side beam of the boom or wheel with

a fixed length of string to control the depth of cut and

center line travel of the ditcher.

9-33

Cutting Curves

The radius of a curve cut while excavating a trench

with the ditcher depends mainly on the density of the

soil excavated. In sandy or loose soil, the radius can be

much less than in hard, compacted, and rocky soil. The

turn for the ditcher should be made cautiously at a slow

digging speed and only to where the boom starts binding

between the trench walls.

Muddy Trenching

The two major problems when trenching in muddy

materials are loss of traction and a buildup of material

in the buckets. The traction can be increased by putting

planking under the tracks or by adding wider crawler

pads. To cope with material sticking to the teeth and

buckets, you can run the digging chain faster, so the

material will not be forced into the cut. In this way, you

do not force and pack wet, sticky material into the bucket

and between the teeth; otherwise, the material in the

bucket gets stuck and cannot empty completely.

Transporting

A ditcher is slow and must be hauled between

jobsites. It must be loaded and unloaded safely and

properly. The design of the ditcher requires that it be

used on a smooth, gradual incline. When loading on a

tilt-bed trailer, you must be careful; the sharp incline of

the trailer could make the ditcher hang up. Additionally,

the smooth tracks of the ditcher tend to slip.