Tractor Unit (Power Unit)

The tractor unit provides moving power for the

paver wheels or tracks and for all powered machinery

on the paver. The tractor unit includes the receiving

hopper, feed conveyor, flow control gates, distributing

augers (or spreading screws), power plant (engine),

transmissions, dual controls, and operator’s seat.

The tractor unit power plant (engine) propels the

paver, pulls the screed (leveling) unit, and provides

power to the other components through transmissions.

Hot mix is deposited in the hopper and is then carried

by the feed conveyor through the flow control gates to

the distributing augers (spreading screws). The augers

distribute the mix evenly across the full width of the

paver, thus providing uniform placement of the mix onto

the roadway surface. These operations are controlled

by the paver operator by means of dual controls within

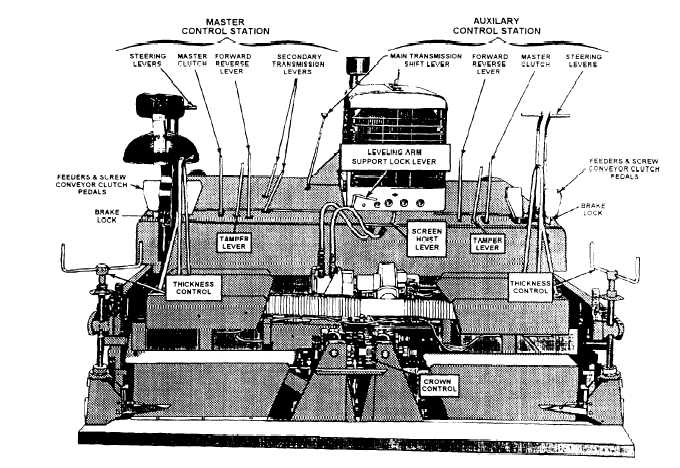

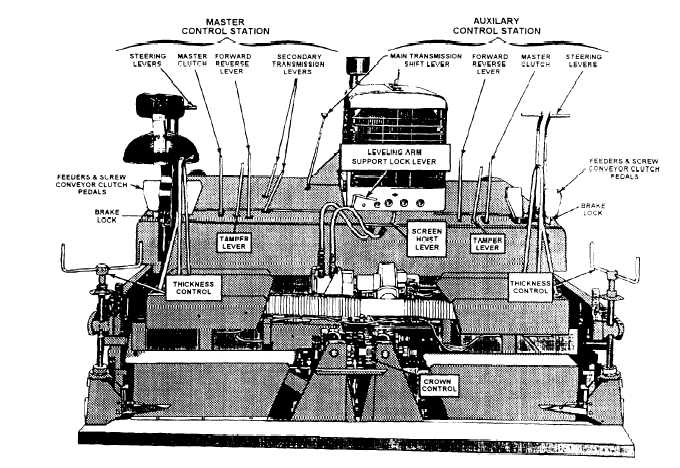

easy reach of the operator’s seat. Figure 16-40 shows

the operating controls of one type of finisher used in the

NCF.

To ensure the paver functions properly, you should

inspect the paver before commencement of paving.

Below are some of the compments you should check.

PAVER TIRES OR TRACKS.— When the paver

is equipped with pneumatic tires, tire condition and air

pressure must be checked. It is particularly important

for the pressure to be the same in the tires on both sides

of the paver.

When the paver moves on tracks

(crawlers), the tracks should be checked to be certain

they are snug but not tight, and the drive sprockets

should be checked for excessive wear. Low tire pressure

or loose tracks can cause unnecessary movement of the

paver, which is transmitted to the screed unit, resulting

in an uneven pavement surface. There should be no

buildup of material on the tires or on the tracks.

GOVERNORS.— The governor on the engine

must also be checked to be sure that there is no periodic

surge in the engine rpm.

When the governor is not

working properly, there can be a lag in power when the

engine is loaded (strained). Such a lag causes temporary

failure of the vibrators or tamping bars in the screed unit,

resulting in a stretch of pavement that is less dense or

Figure 16-40.-Operating controls, Barber-Greene model SA-35 finisher.

16-36