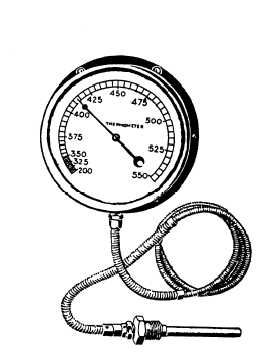

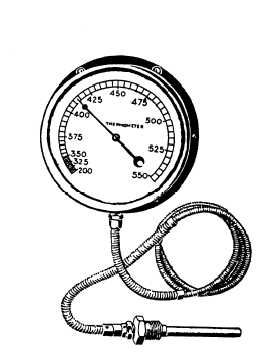

as long as 125 feet, which separates the sensing

bulb from the Bourdon tube and dial (fig. 8-14).

There are three basic types of distant-reading

thermometers: the liquid filled, the gas filled,

and the combination liquid-vapor filled. The

thermometers are filled with fluid (liquid or gas)

at some temperature and sealed. Almost the entire

volume of the fluid is in the sensing bulb.

As the temperature of the bulb changes, the

volume of the fluid tries to change. Since

the volume of the thermometer (sensing bulb,

capillary, and Bourdon tube) is constant, a

pressure change occurs within the thermometer.

This pressure change causes the Bourdon tube to

straighten out (with an increase in pressure),

working a system of levers and gears, which causes

the thermometer pointer to move over the dial and

register temperature.

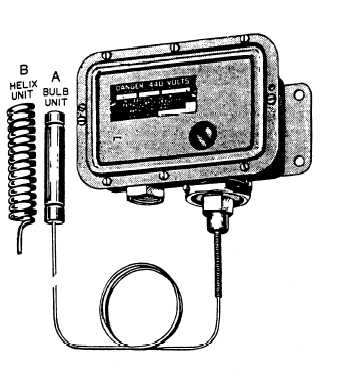

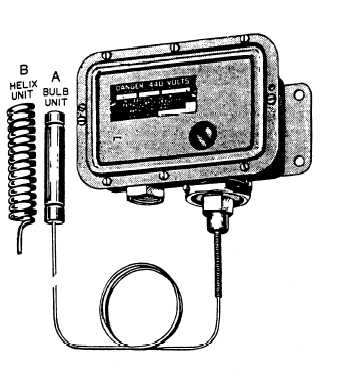

TEMPERATURE SWITCHES

Temperature switches operate from tempera-

ture changes occurring in an enclosure, or in the

air surrounding the temperature-sensing element.

The operation of the temperature switch is similar

to the operation of the pressure switch shown in

figure 8-9; both switches are operated by changes

in pressure. The temperature element is arranged

so a change in temperature causes a change in the

internal pressure of a sealed-gas or air-filled bulb

Figure 8-14.—Distant-reading, Bourdon-tube thermometers.

or helix, which is connected to the actuating device

by a small tube or pipe. Figure 8-15 shows a

temperature switch and two types of sensing

elements.

A temperature change causes a change in the

volume of the sealed-in gas, which causes

movement of a bellows. The movement is

transmitted by a plunger to the switch arm. The

moving contact is on the arm. A fixed contact may

be arranged so the switch will open or close on

a temperature rise. This allows the switch contacts

to be arranged to close when the temperature

drops to a predetermined value and to open when

the temperature rises to the desired value. The

reverse action can be obtained by a change in the

contact positions.

GAUGE SNUBBERS

The irregularity of impulses applied to the

fluid power system by some pumps or air

compressors causes the gauge pointer to oscillate

violently. This makes reading of the gauge not

only difficult but often impossible. Pressure

oscillations and other sudden pressure changes

existing in fluid power systems will also affect the

delicate internal mechanism of gauges and cause

either damage to or complete destruction of the

Figure 8-15.—Temperature switch with two types of sensing

elements. A. Bulb unit. B. Helix unit.

8-8