installations. A typical reservoir for use with

ground and ship installations is shown in figure

9-1. This type of reservoir is made of hot rolled

steel plates and has welded seams. The ends extend

below the bottom of the reservoir and serve as

supports. The bottom of the reservoir is convex,

and a drain plug is incorporated at the lowest

point.

Nonpressurized reservoirs are also used in

several transport-,

patrol-, and utility-type

aircraft. These aircraft are not designed for violent

maneuvers and, in some cases, do not fly at high

altitude. Those aircraft that have nonpressurized

reservoirs installed and that fly at high altitudes

have the reservoirs installed within a pressurized

area. (High altitude in this situation means an

altitude where atmospheric pressure is inadequate

to maintain sufficient flow of fluid to the

hydraulic pumps.)

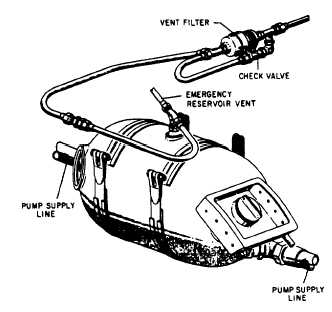

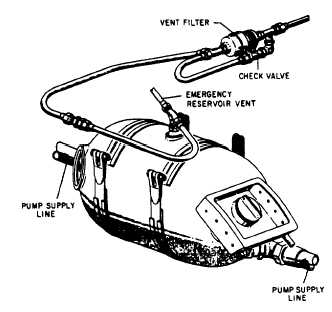

Most nonpressurized aircraft reservoirs are

constructed in a cylindrical shape (fig. 9-2). The

outer housing is manufactured from a strong

corrosion-resistant metal. Filter elements are

normally installed internally within the reservoir

to clean returning system hydraulic fluid. Some

of the older aircraft have a filter bypass valve

installed to allow fluid to bypass the filter if the

filter becomes clogged. Reservoirs that are filled

by pouring fluid directly into them have a filler

(finger) strainer assembly installed in the filler well

to strain out impurities as the fluid enters the

reservoir.

Figure 9-2.—Nonpressurized aircraft reservoir.

The quantity of fluid in the reservoir is

indicated by either a glass tube, a directing gauge,

or a float-type rod, which is visible through a

transparent dome installed on the reservoir.

PRESSURIZED RESERVOIRS

A pressurized reservoir is required in hydraulic

systems where atmospheric pressure is insufficient

to maintain a net positive suction head (NPSH)

to the pump. There are two common types of

pressurized reservoirs—fluid-pressurized and

air-pressurized.

Fluid-Pressurized Reservoir

Some aircraft hydraulic systems use fluid

pressure for pressurizing the reservoir. The

reservoir shown in figure 9-3 is of this type. This

reservoir is divided into two chambers by a

floating piston. The piston is forced downward

in the reservoir by a compression spring within

the pressurizing cylinder and by system pressure

entering the pressurizing port of the cylinder.

The pressurizing port is connected directly to

the pressure line. When the system is pressurized,

pressure enters the pressure port, thus pressurizing

the reservoir. This pressurizes the pump suction

line and the reservoir return line to the same

pressure.

The reservoir shown in figure 9-3 has five

ports—pump suction, return, pressurizing,

overboard drain, and bleed. Fluid is supplied to

the pump through the pump suction port. Fluid

returns to the reservoir from the system through

the return port. Pressure from the pump enters

the pressurizing cylinder in the top of the reservoir

through the pressurizing port. The overboard

drain port is used to drain the reservoir while

performing maintenance, and the bleed port is

used as an aid when servicing the reservoir.

Air-Pressurized Reservoirs

Air-pressurized reservoirs, such as the one

shown in figure 9-4, are currently used in many

high-performance naval aircraft. The reservoir is

cylindrical in shape and has a piston installed

internally to separate the air and fluid chambers.

Air pressure is usually provided by engine bleed

air. The piston rod end protrudes through the

reservoir end cap and indicates the fluid quantity.

The quantity indication may be seen by inspecting

the distance the piston rod protrudes from the

reservoir end cap. The reservoir is provided with

9-2