charge of air or an inert gas such as nitrogen.

Sometimes the amount of air charge is limited to

the volume within the accumulator; other

installations may use separate air flasks which are

piped to the air side of the accumulator. Piston

accumulators may be mounted in any position.

The gas portion of the accumulator may be

located on either side of the piston. For example,

in submarine hydraulic systems with tailrod

pistons, the gas is usually on the bottom and the

fluid on top; in surface ships with floating pistons,

the gas is usually on the top. The orientation of

the accumulator and the type of accumulator are

based upon such criteria as available space,

maintenance accessibility, size, need for external

monitoring of the piston’s location (tailrod

indication), contamination tolerance, seal life, and

safety. The purpose of the piston seals is to keep

the fluid and the gas separate.

Usually, tailrod accumulators use two piston

seals, one for the air side and one for the oil side,

with the space between them vented to the

atmosphere through a hole drilled the length of

the tailrod. When the piston seals fail in this type

of accumulator, air or oil leakage is apparent.

However, seal failure in floating piston or

nonvented tailrod accumulators will not be as

obvious. Therefore, more frequent attention to

venting or draining the air side is necessary. An

indication of worn and leaking seals can be

detected by the presence of significant amounts

of oil in the air side.

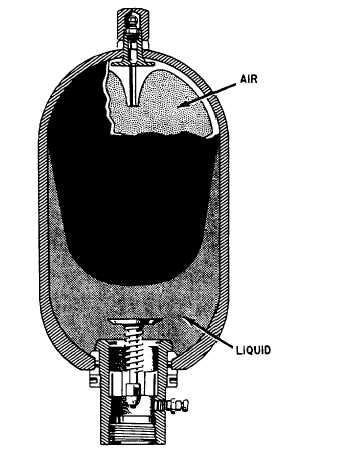

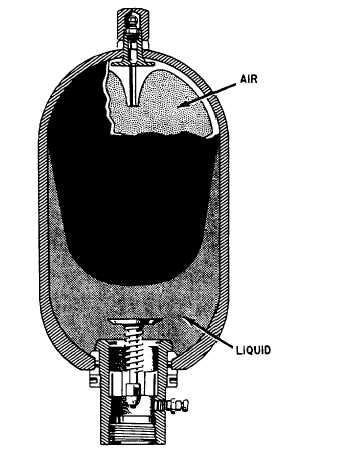

BLADDER-TYPE ACCUMULATORS

Bladder- or bag-type accumulators consist of

a shell or case with a flexible bladder inside the

shell. See figure 9-7. The bladder is larger in

diameter at the top (near the air valve) and

gradually tapers to a smaller diameter at the

bottom. The synthetic rubber is thinner at the top

of the bladder than at the bottom. The operation

of the accumulator is based on Barlow’s formula

for hoop stress, which states: “The stress in a

circle is directly proportional to its diameter and

wall thickness.” This means that for a certain

thickness, a large diameter circle will stretch faster

than a small diameter circle; or for a certain

diameter, a thin wall hoop will stretch faster than

a thick wall hoop. Thus, the bladder will stretch

around the top at its largest diameter and thinnest

wall thickness, and then will gradually stretch

downward and push itself outward against the

walls of the shell. As a result, the bladder is

capable of squeezing out all the liquid from.

Figure 9-7.—Bladder-type accumulator.

the accumulator. Consequently, the bladder

accumulator has a very high volumetric efficiency.

In other words, this type of accumulator is

capable of supplying a large percentage of the

stored fluid to do work.

The bladder is precharged with air or inert gas

to a specified pressure. Fluid is then forced into

the area around the bladder, further compressing

the gas in the bladder. This type of accumulator

has the advantage that as long as the bladder is

intact there is no exposure of fluid to the gas

charge and therefore less danger of an explosion.

DIRECT-CONTACT GAS-TO-FLUID

ACCUMULATORS

Direct-contact gas-to-fluid accumulators

generally are used in very large installations where

it would be very expensive to require a piston-

or bladder-type accumulator. This type of

accumulator consists of a fully enclosed cylinder,

mounted in a vertical position, containing a liquid

9-6